|

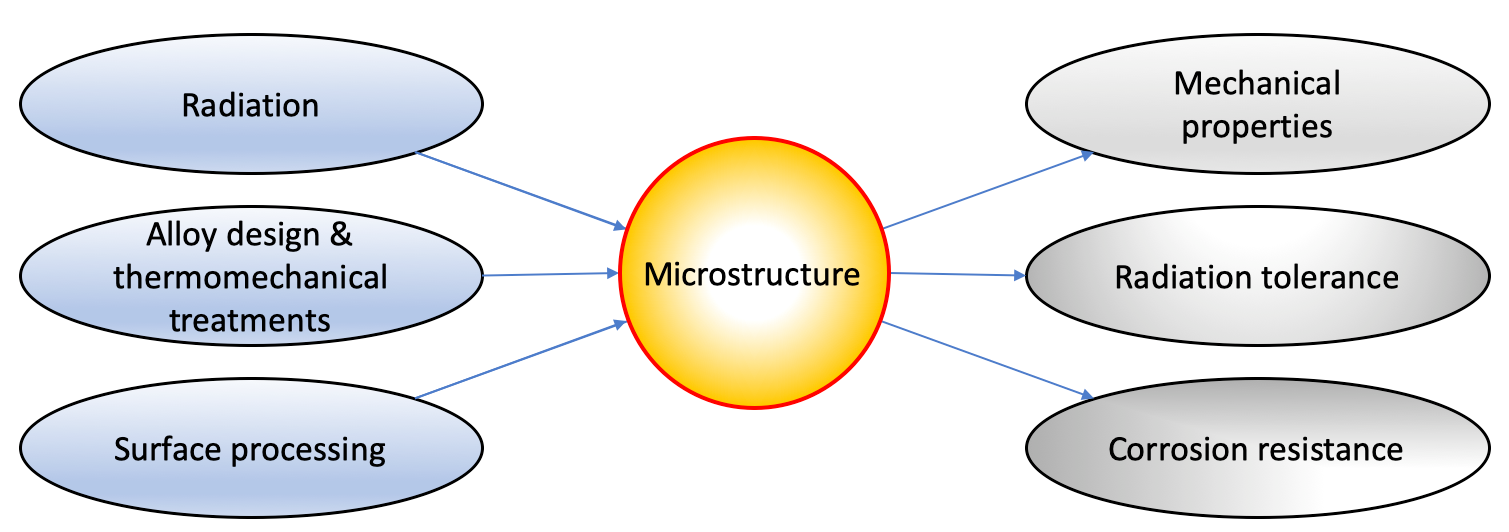

| We study and understand the microstructure – property relationships of advanced materials for energy applications. We use modern experimental and material modeling tools to design, process, characterize and test materials and rationalize their performance through microstructural evolution. We are engaged to improve the predictability of material degradation under harsh environment and accelerate the development and processing of new materials for the more challenging service environments. We are actively developing the following techniques to advance the frontiers of knowledge. |

| Nanomechanical Testing | |

|

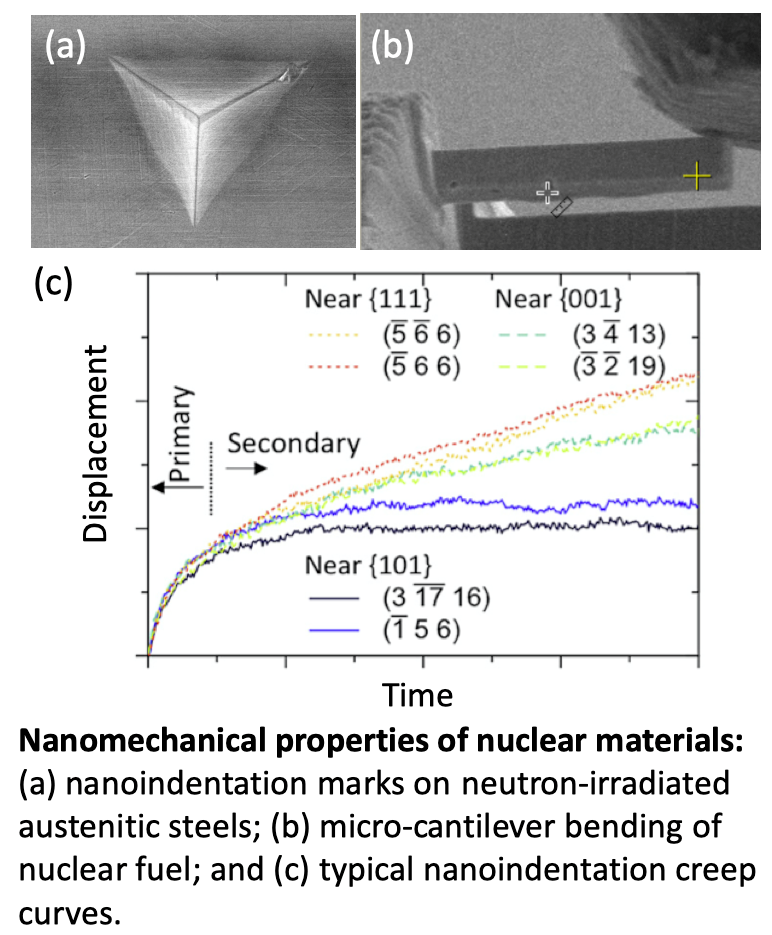

Nanomechanical testing probe local mechanical properties, such as hardness, elastic modulus, fracture stress and even microscopic properties related to fatigue and creep performance. The local properties can be directly correlated to the microstructure, which depends on material design, fabrication and processing, and exposure to severe environments. Thus, such microstructure – property relationship is the core in material design and optimization and in the prediction of material degradation under service conditions.

For nuclear material studies, nanomechanical testing provides bonuses in the rapid turnaround, small sample requirement, and small deformation volume that matches the shallow damage depth of typical ion irradiation. We applied nanomechanical testing to irradiated structural and fuel materials to understand the effects of radiation damage on mechanical properties. We recently found that nanoindentation creep properties are highly sensitive to dislocation locking and blocking effects and provide an additional dimension to understand the microstructure – property relationships. |

|

Publications: The effect of grain orientation on nanoindentation behavior of model austenitic alloy Fe-20Cr-25Ni |

|

| Microstructure Characterization | |

|

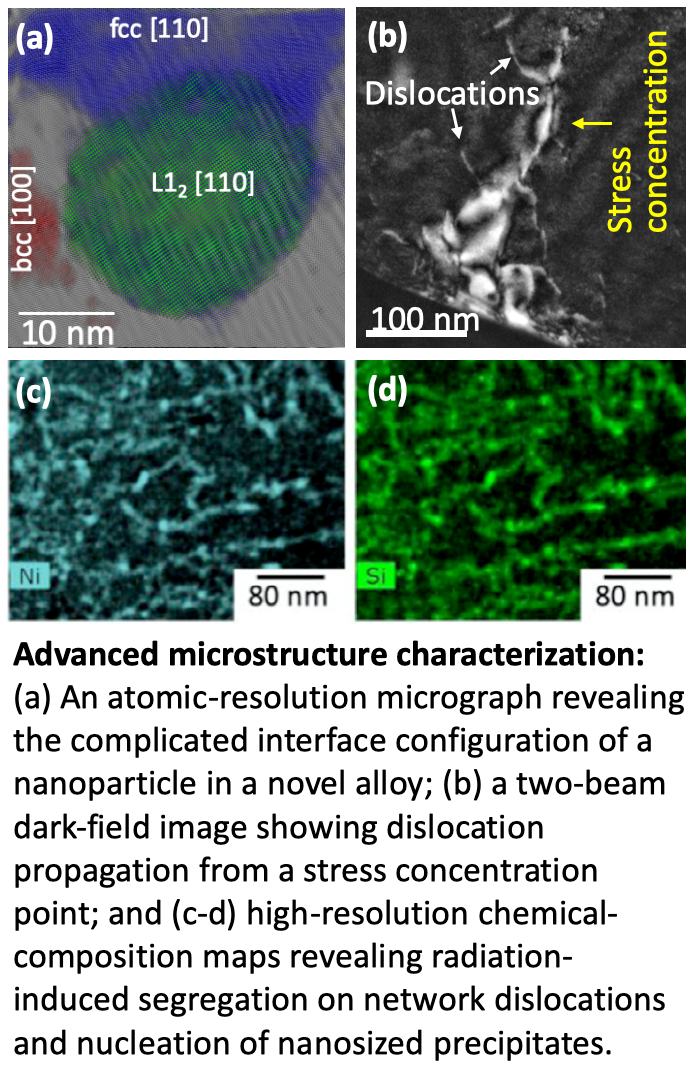

Our expertise in microstructure characterization using advanced electron microscopes and other techniques allows us to understand the material behavior from a microstructure perspective. We investigate the atomistic configurations of microstructure features, either engineered to boost the material’s performance or caused by extreme-environment exposure. With the aid of focused-ion-beam technique, we conduct post-mortem examination on samples underwent irradiation, corrosion exposure and mechanical tests and understand the microstructural mechanisms of materials’ response to these conditions. With the powerful ChemiSTEM system at OSU, we can also reveal the chemistry distribution at nanoscale resolution and correlate the spatial distribution of chemistry to microstructural features. Understanding the microchemistry – microstructure correlation is a critical task for nuclear materials, which are subjected to radiation that accelerates the synergistic evolution of microstructure and microchemistry.

We have experience applying advanced microstructure characterization to understanding the thermodynamics, radiation tolerance, corrosion and deformation mechanisms of a wide range of materials. The insights from microstructural analysis have benefit both material designers and users who need to predict the material performance under harsh environments. |

|

Publications: Microstructure study of U–35 wt.% Zr alloy after quick annealing at 650 ºC Steam oxidation behavior of Ni-base superalloys 690, 725 and X-750 at 600 and 650º C High-temperature strengthening mechanisms of Laves and B2 precipitates in ferritic alloys |

|

| Laser Shock Peening | |

|

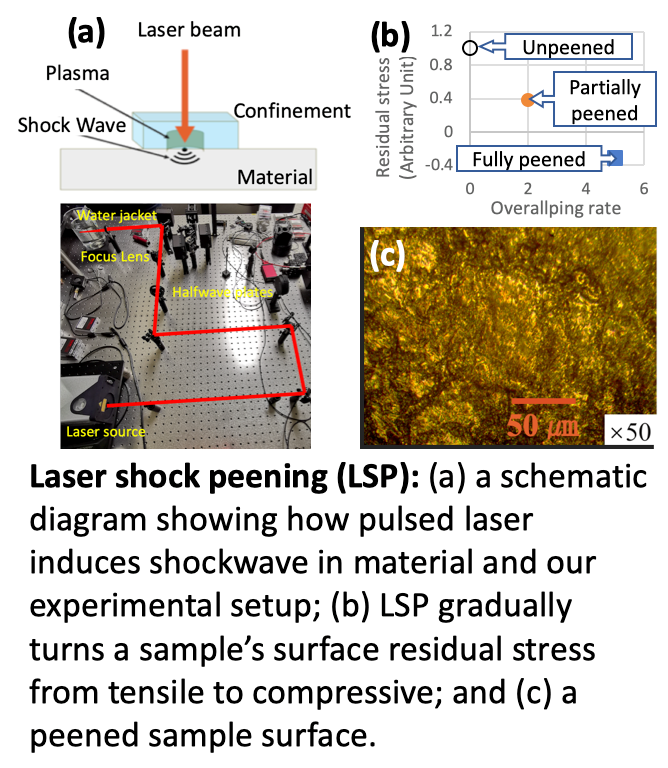

Surface modification techniques are economical and efficient methods to enhance the materials’ resistance to failure when serving in harsh environment. Laser shock peening (LSP), for example, has been applied to light-water-reactor structural materials and waste storage cannisters to enhance the tolerance against stress corrosion cracking. Through a holistic compositional and processing design, LSP may introduce beneficial microstructures that are stable against thermal aging and radiation damage at the Generation IV nuclear reactor conditions. In addition, the potential of LSP techniques on non-metallic materials and additive-manufactured materials has also been recently demonstrated.

As a demonstration, we applied LSP to a newly developed accident tolerant material. As shown in the left figures, LSP mitigated the residual tensile stress in the material by introducing a surface compressive stress. As a result, the mechanical performance especially the resistance to corrosion and cracking is expected to be enhanced. |

| Modeling | |

|

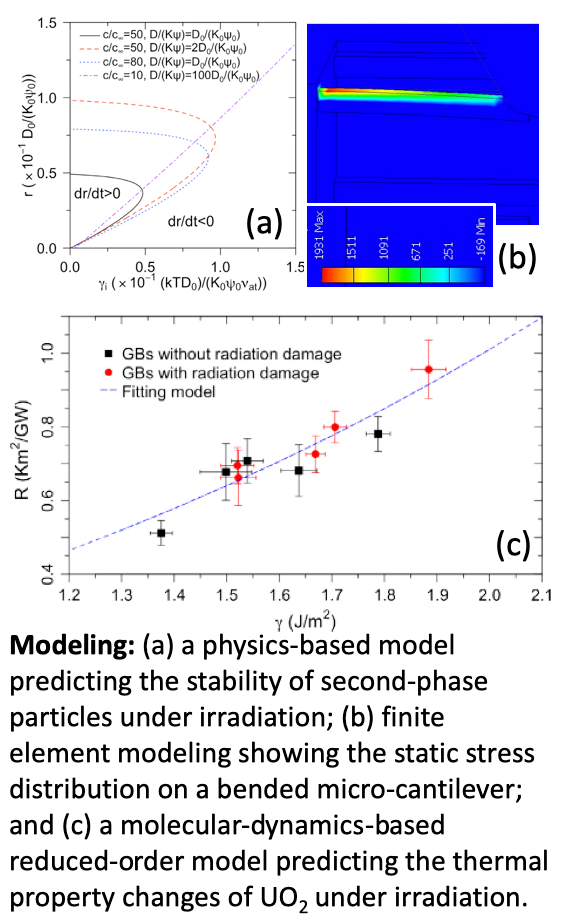

We combine material modeling with experiments in our research. Physics based models provide guidance to the experimental design but also can be fitted to experimental results to extrapolate physics parameters that cannot be directly measured from experiments. In addition, the data fitting extrapolates to model to predict material performance beyond the experimental conditions. Such an example can be seen in Figure (a) to the left and the related publication.

The comparable spatial scales between transmission electron microscopy and atomistic simulations allow the later to be performed and reveal the mechanisms behind experimental observations. We apply molecular dynamics simulations to study material behavior under different conditions such as radiation and mechanical loading. The revealed defect development and evolution and the interactions between dislocations and defects provide mechanistic understandings and input to larger scale predictive models. |

|

Enhanced diffusion of Cr in 20Cr-25Ni type alloys under proton irradiation at 670 ºC Molecular dynamics simulations of grain boundary thermal resistance in UO2 |

|