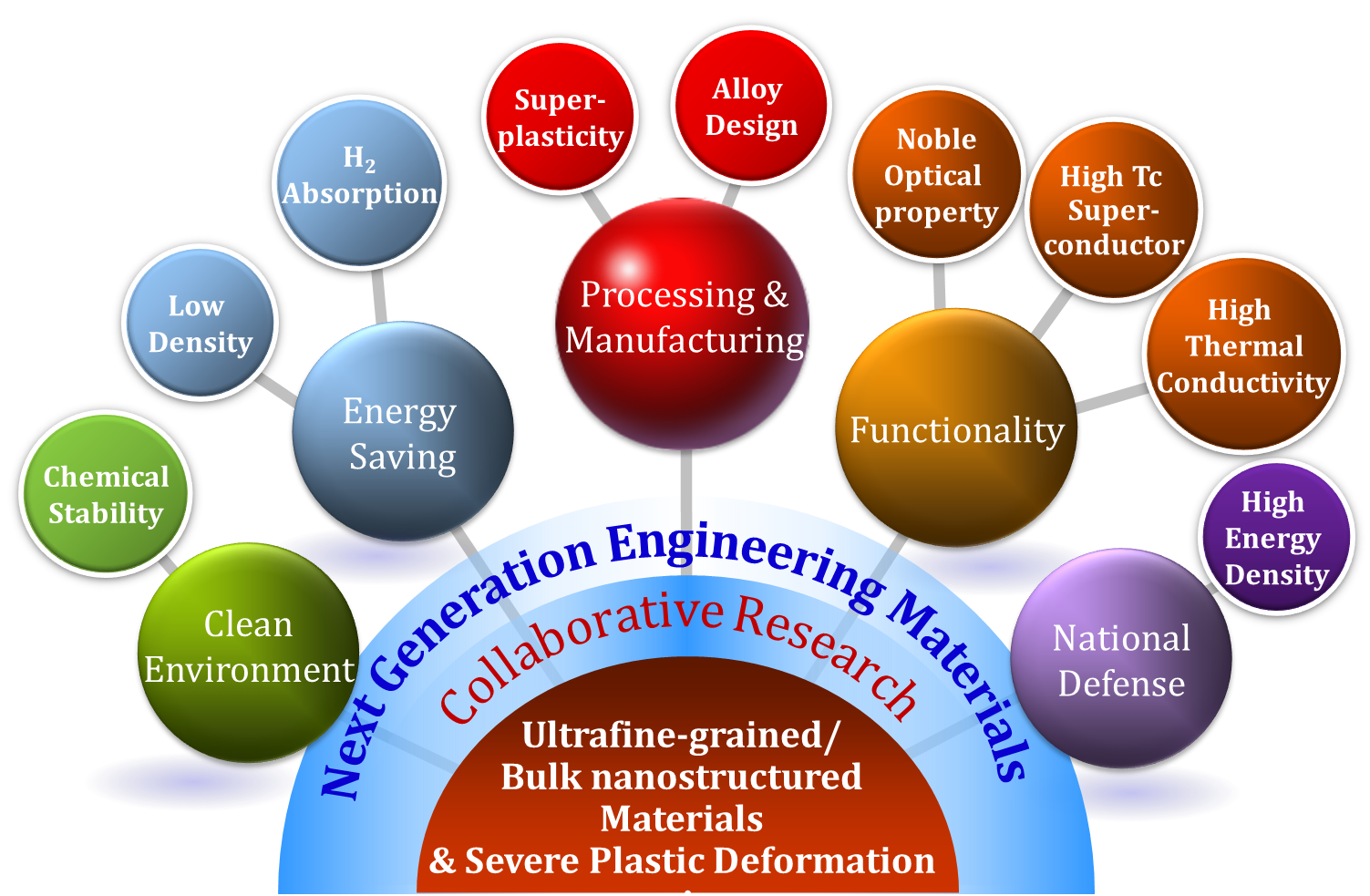

Our group focuses the research on the processing of ultrafine-grained (UFG) materials and bulk nanostructured materials (BNM) using severe plastic deformation (SPD) and characterizing their unique and enhanced physical and mechanical properties. It is distinctly defined that UFG materials are submicron-crystalline materials with grain sizes in the range of 100–1000 nm and nanostructured materials with grain sizes below 100 nm. Such materials usually have superior mechanical and physical properties including high strength, improved corrosion resistance, and higher wear resistance.

SPD is a special processing technique that introduces very high strains without any significant changes in the overall dimensions of the workpieces. Our research specialty includes, through the application of SPD, the production of bulk nanostructured solids having both exceptional strengths at ambient temperatures and excellent forming capabilities at elevated temperatures. Specifically, our investigations utilize processing by a High-Pressure Torsion (HPT) technique and evaluate the effect of severe plastic deformation on the microstructural evolution and the mechanical properties of structural/lightweight metallic materials.

Contact Information:

Kawasaki's Office - Dearborn Hall room 306

Lab - Dearborn Hall room 5

Faculty of Materials Science School of Mechanical, Industrial and Manufacturing Engineering

Oregon State University

Corvallis, OR 97331

541-737-4571