A Heterogeneous Multi-sensor System for Eagle Detection and Identification, Deterrent and Blade Collision Detection has been designed and tested.

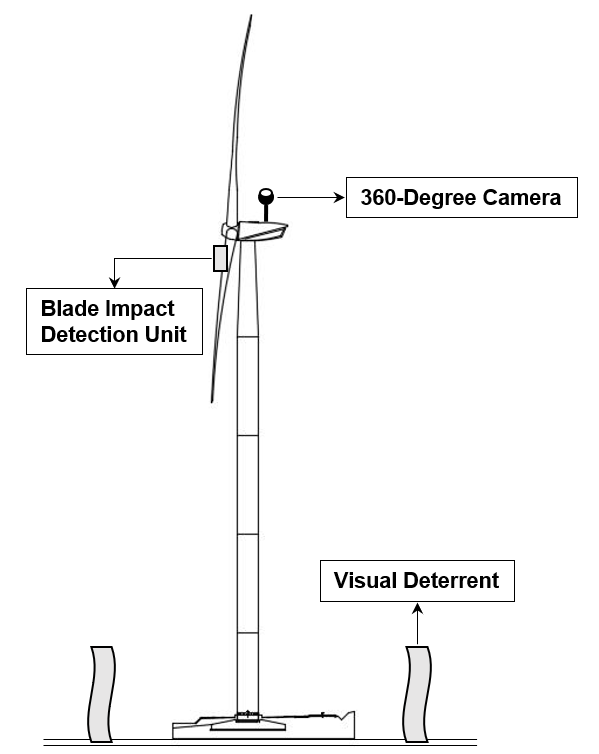

The system consists of three modules as shown in Figure 1: 1) The monitoring of the entire airspace view surrounding a wind turbine by a single 360-degree field of view camera, 2) A kinetic ground-based inflatable visual deterrents, and 3) Blade impact detection unit installed at the root of each blade for collision monitoring. The 360-degree camera uses computer vision and artificial intelligence techniques to determine if an eagle is flying towards the wind turbine. In the event of positive eagle identification, an array of kinetic inflatable visual deterrents are triggered automatically. The blade impact detection unit monitors continuously vibration signals automatically storing data in a window around an event including visual images, providing data for impact confirmation and species recognition.

Target detection and eagle identification.

A 360-degree field of view camera, as shown in Figure 2, is installed on top of the wind turbine nacelle (Fig.1) for airspace monitoring. Computer vision techniques are applied to the video stream, providing real-time feedback about the presence of moving objects and their flight paths with respect to the turbine structure. A deep learning artificial intelligence post processing algorithm provides real-time eagle identification of the detected mobile target.

Eagle Deterrent

Studies by biologists have found eagles avoidance behavior to objects increasing in size, and a level of aversion to human-like figures. Hence, anthropomorphic kinetic inflatable visual deterrents, as shown in Figure 3, are selected for automatic deployment around the wind turbine to display a human-form dynamic motion. Deterrent colors are custom made maximizing eagle’s visual sensitivity and making them more distinguishable from the background in the avian perspective. Deterrents are deployed automatically by the control computer after a positive eagle identification signal from the eagle detection and identification sub-system.

Impact Detection

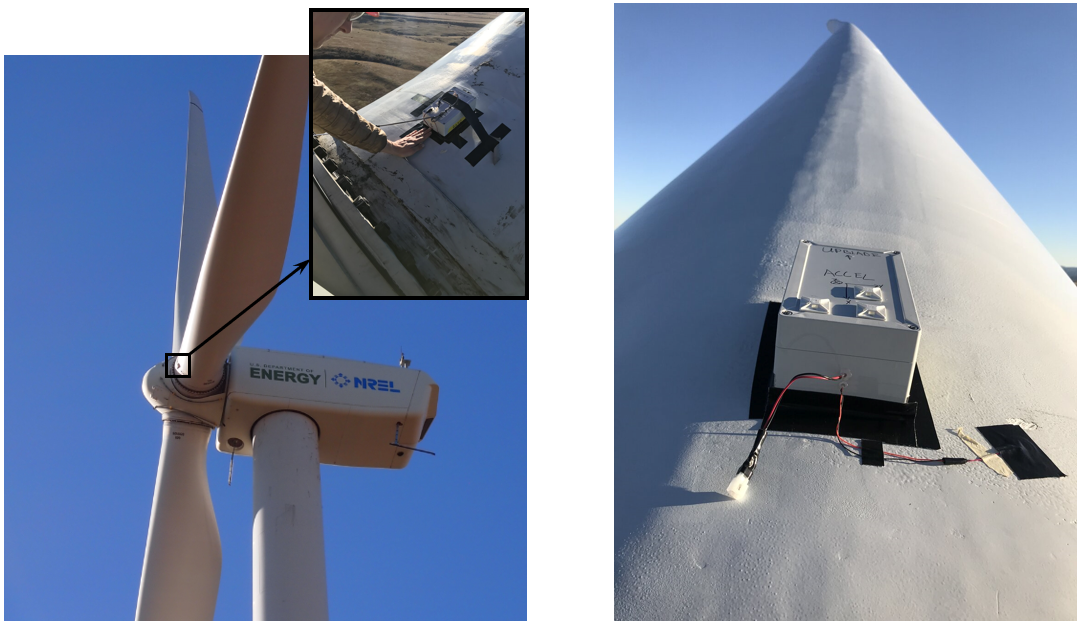

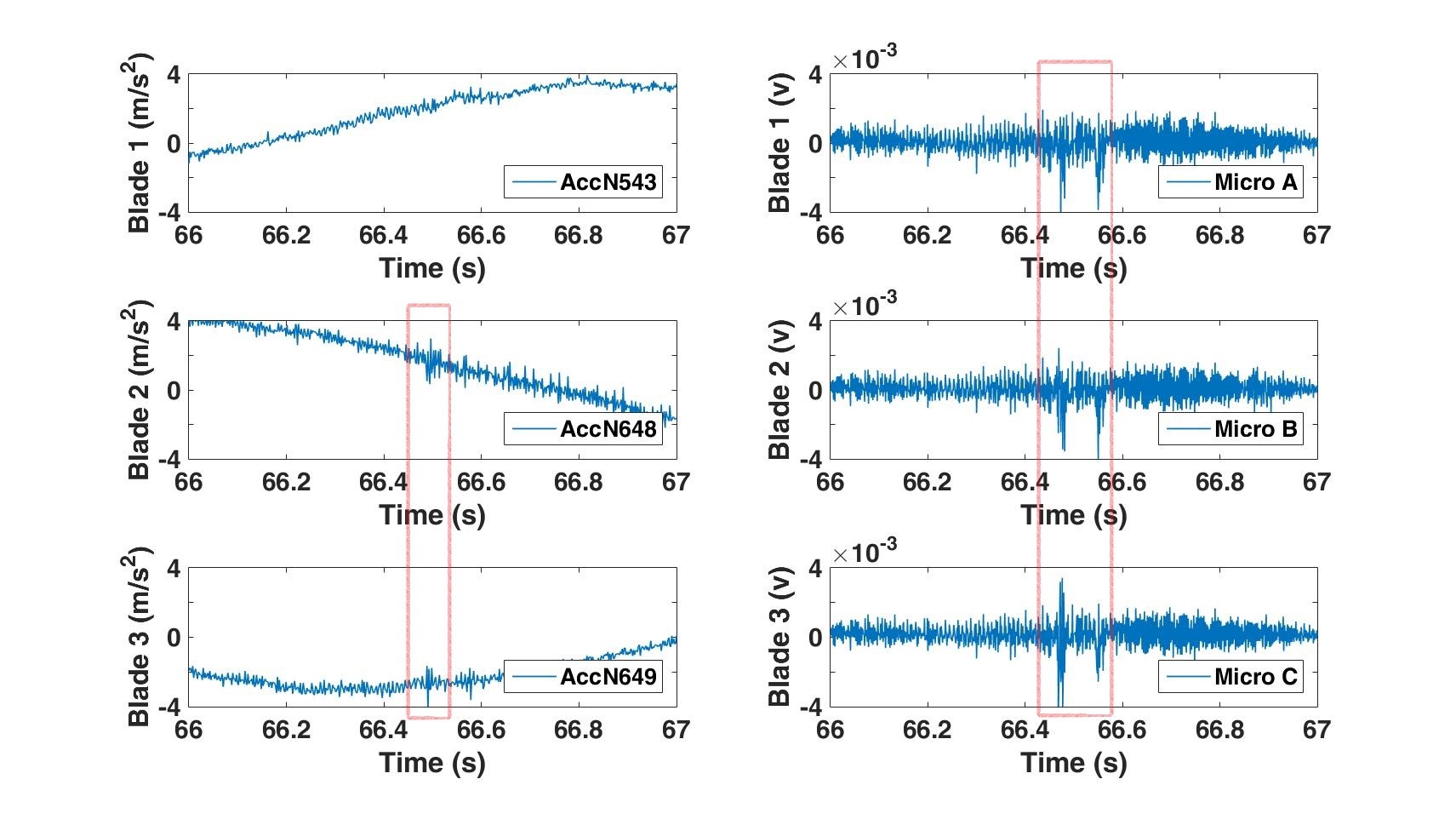

A blade impact detection unit (BID), shown in Figure 4, is installed at the root of each blade for continuous and automatic collision monitoring. Three primary sensors are integrated in each BID, including: 1) A micro camera, 2) An inertial measurement unit (IMU) and 3) A contact microphone. The camera, automatically triggered by the detected event, provides visual images, in a window before and after an impact, for event confirmation and taxonomic identification. All modules can continuously stream and save data to the central processing controller onboard. Sample plots of vibration signals collected by accelerometer and contact microphone sensors during an impact event are illustrated in Figure 5. The BID could be reconfigured to perform other data gathering and analysis as blade health or lighting strike monitoring.

Blade-Impact Simulation

A compressed-air launcher, as shown in Figure 6, was designed and assembled to create artificial impacts on blades using tennis balls, small potatoes or other desired projectiles. The launcher is barreled to the size of a regular tennis ball, and it is capable to launch one or two tennis balls simultaneously. Multiple impacts on one blade can be achieved, as well as a relatively control on which area of the blade to strike. By choosing tennis balls and various sizes and masses of projectiles, it is possible to simulate impacts with different levels of kinetic energy. The system has achieved a significant blade strikes versus shots ratio during field tests at the NREL National Wind Technology Center and at the Mesalands Community College.

Advanced Blade Vibrations Signal Processing

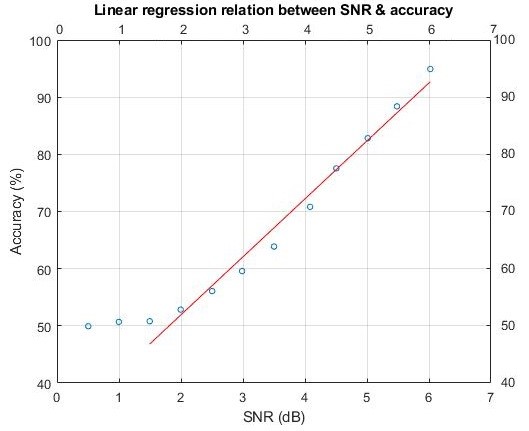

Traditional vibration-based monitoring techniques are not well adapted for non-periodic event detection, typical of blade-strike. Furthermore, when in presence of significant and uncertain background noise, especially when the signal-to-noise ratio is low, an advanced data processing technique is critical. Machine learning algorithms as support vector machine have been successfully applied to blade-impact detection on real and simulated data. Simulation results, shown in Figure 7, indicate a linear regression relationship between signal-to-noise ratio and the model overall performance, defined as accuracy in % of true positive event detection.

Acknowledgements

The authors would like to thank US Department of Energy Efficiency & Renewable Energy office under Funding Opportunity Announcement DE-FOA-0001554 Wind Energy – Eagle Impact Minimization for funding.

Additionally thanks to the following colalborators:

Selection of Publications and Presentations: