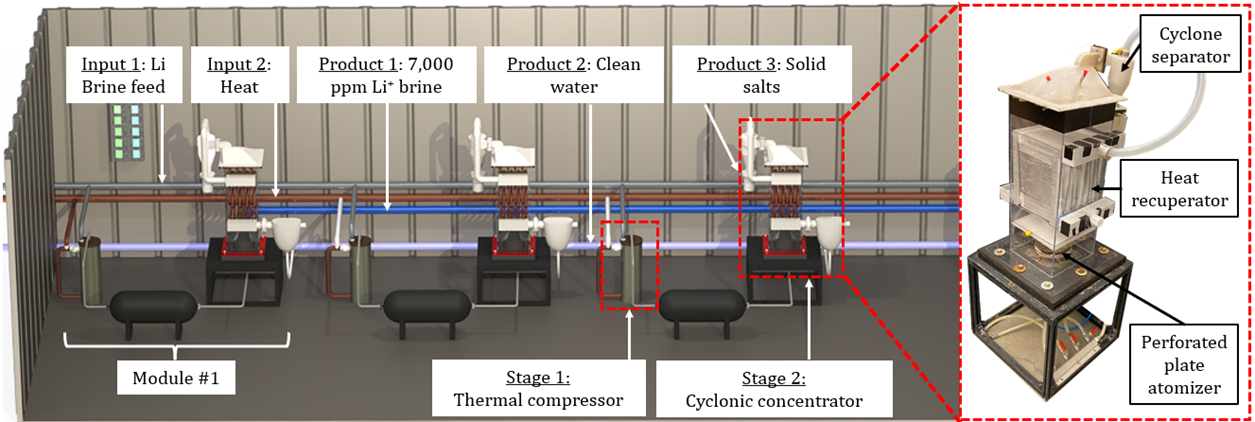

Current seawater mining technologies treat many minerals as byproducts and create environmentally-damaging waste. The economic recovery of these materials would offset clean water production cost and mitigate brine disposal pollution. Espiku’s seawater mining process has shown scientific feasibility for clean and cost-effective lithium extraction from geothermal brine using low-grade heat from solar energy.

| Technology | Advantages | Disadvantages |

|---|---|---|

|

Solar Pond |

- Passive process - Minimum maintenance - Uses low-grade heat from solar energy |

- Takes an exceedingly long time - Depletes water resources and is environmentally damaging - Hinders extraction of Li+ |

|

Ion Exchange |

- Reduces concentration time - Space-efficient - Has expanded reserves |

- Fouling of ion exchange resins - Expensive infrastructure - Requires high-grade heat |

| Electrodialysis |

- Reduces concentration time - Space-efficient - Has expanded reserves |

- Complicated to control - Expensive electricity infrastructure - Fouling of membranes - Requires high-grade heat |

|

Our Process |

- Uses low-grade heat (< 150 oC) - Clean and environmentally benign - Produces clean water |

-Still at lab scale (pilot scale tests will be demonstrated) |

Brine is atomized to reach desired Li+ concentrations while precipitating out other cations. Li+ is then chemically treated to produce Li2Co3 with a Li+ recovery of 90%. Our system can increase Li+ concentrations from 160 ppm to 7000 ppm and reduces GHG emissions by 70%.

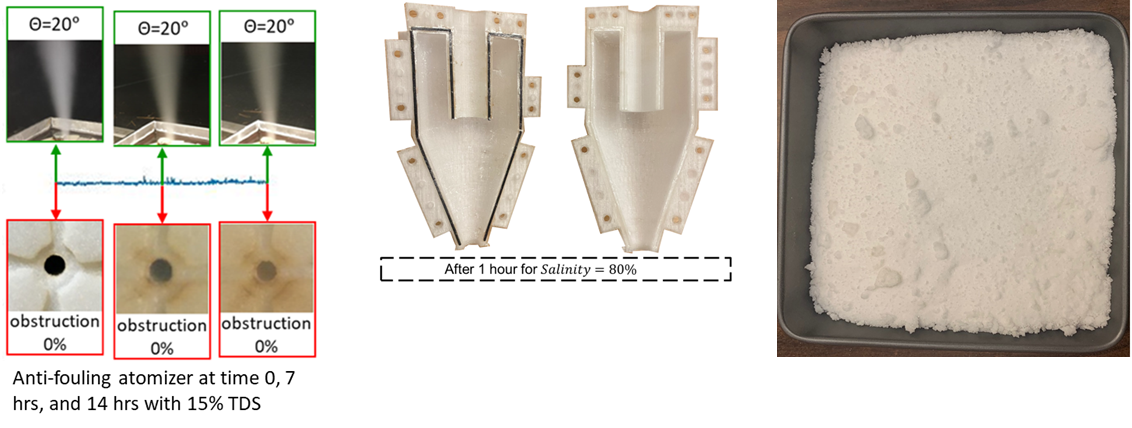

Espiku’s anti-fouling atomizer demonstrates 3.5-80% brine with separation efficiencies of over 99.8%. It doesn’t require high pressures or temperatures or expensive materials.