The Nuclear Materials and Metallurgy research group has access to a wide variety of alloy fabrication, sample preparation, and material testing equipment. Many of our unique research capabilities are accessible to OSU and external customers; please contact Professor Julie Tucker (Julie.Tucker@oregonstate.edu) for pricing and additional information.

The NMM isothermal aging laboratory has multiple benchtop muffle furnaces with capacities that range from 5.8 liters to 36 liters and temperatures from 300 °C up to 1400 °C long term (thousands of hours), or up to 1600°C short term (hours). The mean temperature is maintained at +/-5°C (default) with +/- 2 °C over thousands of hours is not uncommon. We have a maintenance plan that includes spare parts and back up furnace capacity such that in the event of equipment failure a treatment can continue without extended delay, generally less than 3 days. Our temperature monitoring and control system includes multiple thermocouples for each furnace with the reported data evaluated using statistical process control methods in the monitoring of the long-term stability of the furnaces, thermocouples and the data acquisition system. Our thermocouple library includes types (K, N, B, J, E, C, R, S), and calibration assets include a high accuracy thermowell (Fluke 9144), and a secondary platinum resistance thermometer (sPRT) (Fluke 5609). The lab is located at the Advanced Technology and Manufacturing Institute (ATAMI) on the Corvallis HP, Inc. campus.

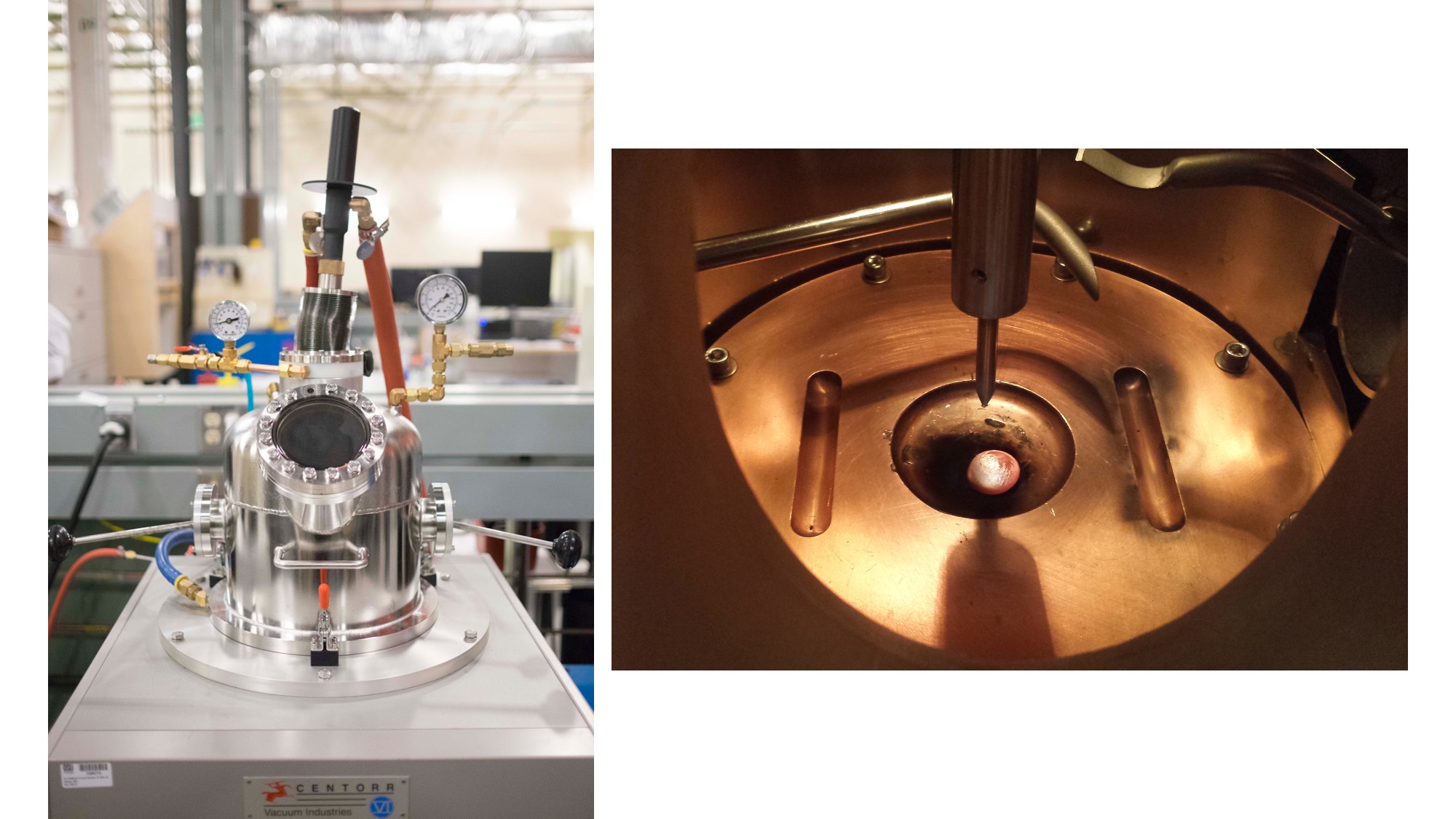

The Centorr 5BJ Arc Melting Furnace is complete with a 5 L, stainless steel bell jar assembly with a water-cooled copper hearth and electrode (stinger) capable of up to 650 amps. Multiple hearth plates are available for fabricating alloy buttons ranging from 100-400 g in size. The chamber can be evacuated by means of the vacuum pumping system and then back-filled with the desire inert gas (He or Ar). The system is ideal for alloys development or fabricating model alloys to facilitate fundamental understanding.

The NMM lab owns a MicroMaterials NanoTest vantage nanoindenter for local mechanical testing. The nanoindenter has a loading range of 0.05 to 500 mN on the low load head and 500 mN to 30 N on the high load head. Typically, a diamond Berkovich indenter is used for hardness and modulus determination. The system is on a floating minus-k table to minimize vibrations. Our nanoindenter can be used by OSU and external customers; please inquire with Professor Julie Tucker (Julie.Tucker@oregonstate.edu).

Additionally, Professor Tianyi Chen (http://research.engr.oregonstate.edu/chen/) in the NSE department also owns a nanoindenter which can be used in-situ in the Quanta 3D SEM in the Electron Microscopy facility.

The NMM lab owns a Sartorius ME36S microbalance for corrosion weight gain measurement and alloy development. The microbalance has a maximum weighing capacity of 31g and a minimum sample weight of 5 mg. The readability is 1 µg with a repeatability of ± ≤ 2 µg. The system is supported by a marble balance table to dampen vibrations. The microbalance is located in Dearborn 212.

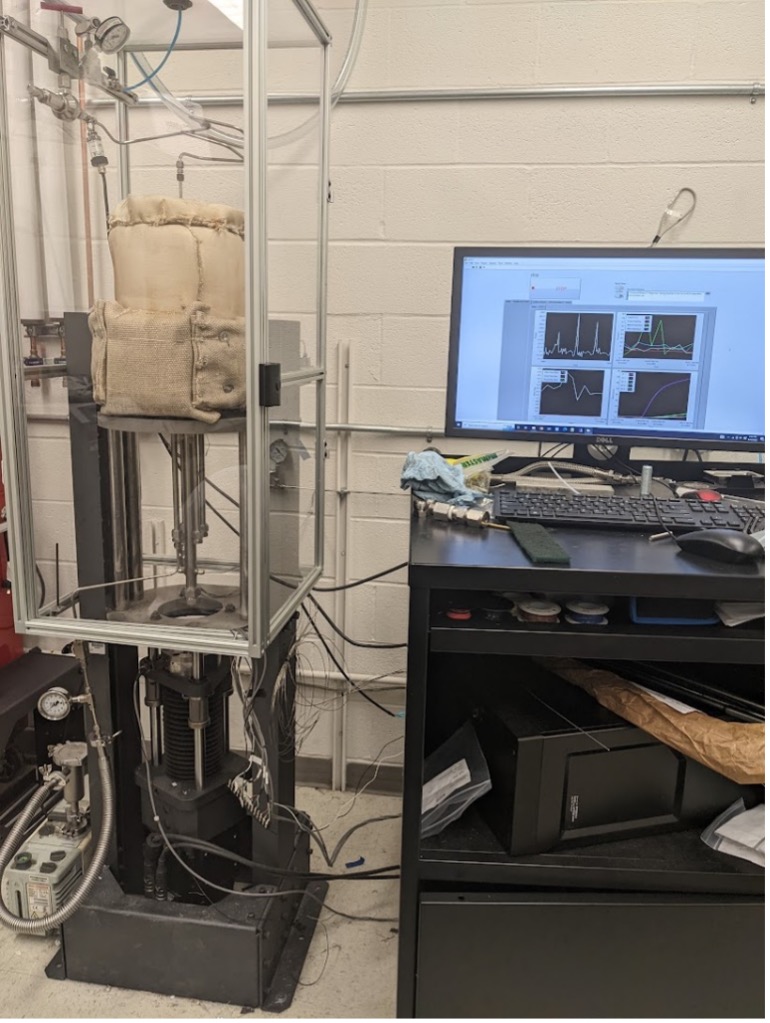

The GLFA was constructed to perform mechanical testing and studying environmentally assisted crack growth in high temperature gases. The autoclave chamber is capable of holding pressurized gases of up to 20 MPa (2900 psi) at temperatures up to 650°C. The autoclave is mated to a load frame capable of testing samples in situ. Many gaseous environments are possible including supercritical CO2 and inert Ar.

This equipment was built in and operated in collaboration with Prof. Sam Briggs and the Nuclear Materials Degradation Research Group (http://research.engr.oregonstate.edu/briggs/).

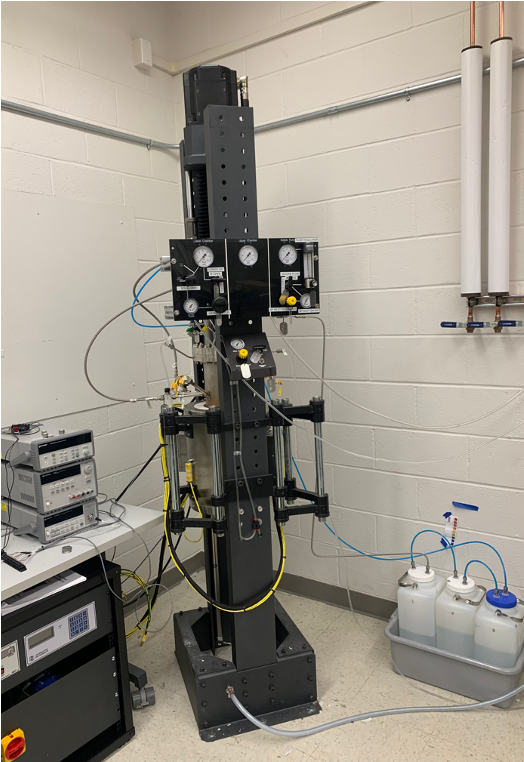

The Molten Salt Load Frame is comprised of an actuator mated to a furnace that enables simultaneous mechanical testing and salt immersion in FLiNaK. The MSLF is capable of performing in situ fracture mechanics based environmentally assisted crack growth testing in a two-chamber molten salt loop. Current projects include performing slow strain rate and fatigue crack growth tests using DCPD to monitor crack growth. The facility was developed via a collaboration between Kairos Power, Parrington Instruments, and Oregon State University and is shared between the NMM and Professor Samuel Briggs’s groups. This equipment was built in and operated in collaboration with Prof. Sam Briggs and the Nuclear Materials Degradation Research Group (http://research.engr.oregonstate.edu/briggs/).

The Salt Prototyping and Development Environment is a modified glovebox capable of performing rapid testing of molten salts. A three-zone furnace with a ceramic crucible allows for facile swapping of salts. The modular lid also allows for more experimental capabilities enabling the implementation of electrochemical monitoring, static corrosion tests, and device benchmarking in one facility. The facility is owned by Professor Samuel Briggs’s group. This equipment was built in and operated in collaboration with Prof. Sam Briggs and the Nuclear Materials Degradation Research Group (http://research.engr.oregonstate.edu/briggs/).

The NMM group manages the metallographic preparation laboratory. Most equipment is located in Dearborn 212. This laboratory hosts a collection of sample preparation resources including:

The Materials Science Program and the School of Mechanical, Industrial, and Manufacturing Engineering have shared resources including:

For our capabilities related to welding and joining please check out the Metals Manufacturing Research Lab webpage.

The Machining and Products Realization Lab provides a full host of machining equipment and CNC machines, allowing fabrication of a wide variety of items. Standard welding equipment is also available: https://mime.oregonstate.edu/mime-machining-and-product-realization-laboratory

The NMM lab has access to ATAMI shared equipment located on the Corvallis HP campus: https://atami.oregonstate.edu/ATAMI_tools

The College of Engineering at OSU supports and maintains a High Performance Computing Cluster with 1,800 cores and an estimated performance of 16+ Terra Flops. A total of 514 CPUs with a total of 2.1 TB RAM are dedicated to the NMM group. The NMM also has a license for the first principles software, VASP.

The OSU Electron Microscopy facility has three scanning electron microscopes (SEM) with abilities for energy dispersive x-ray spectroscopy (EDS) composition measurements, focused ion beam (FIB) and electron backscatter diffraction (EBSD), a transmission electron microscope (TEM), several optical microscopes, and sample preparation equipment. Additional information is available on their website: https://emfacility.science.oregonstate.edu/