Metallic glasses are a unique class of metals with a disordered atomic structure, unlike most metals that have an ordered atomic arrangement. This structure gives them exceptional strength and hardness, but also makes them brittle and prone to breaking when stretched, limiting their practical applications since their discovery in the 1960s. Researchers have been exploring ways to improve their flexibility by introducing tiny soft zones, known as shear bands, which can absorb stress and allow limited deformation. However, current methods cannot precisely control the formation and behavior of these zones. This award supports fundamental research to develop a new processing method that creates carefully designed patterns of shear bands, enabling metallic glasses to bend and stretch without breaking. The approach offers a cost-effective way to modify their internal structure using laboratory-scale testing and processing tools not traditionally used in metal manufacturing, requiring minimal capital investment. By enhancing both strength and ductility, this project expands the potential of metallic glasses for advanced engineering and clean energy technologies.

This work represents a collaborative effort with Prof. Brian Bay at OSU aimed at characterizing the tensile properties and deformation behaviors of copper-based thin films fabricated through electrodeposition.

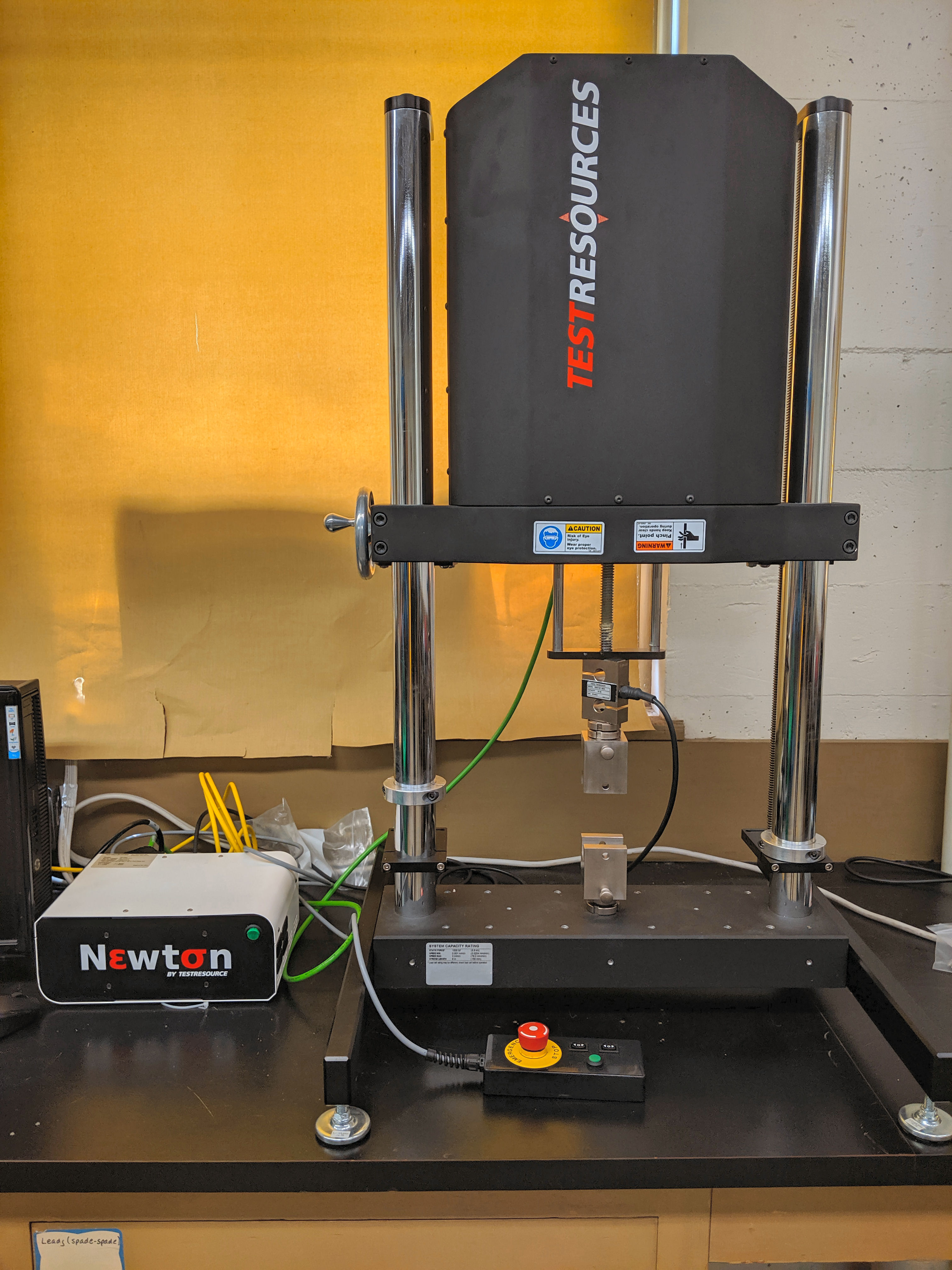

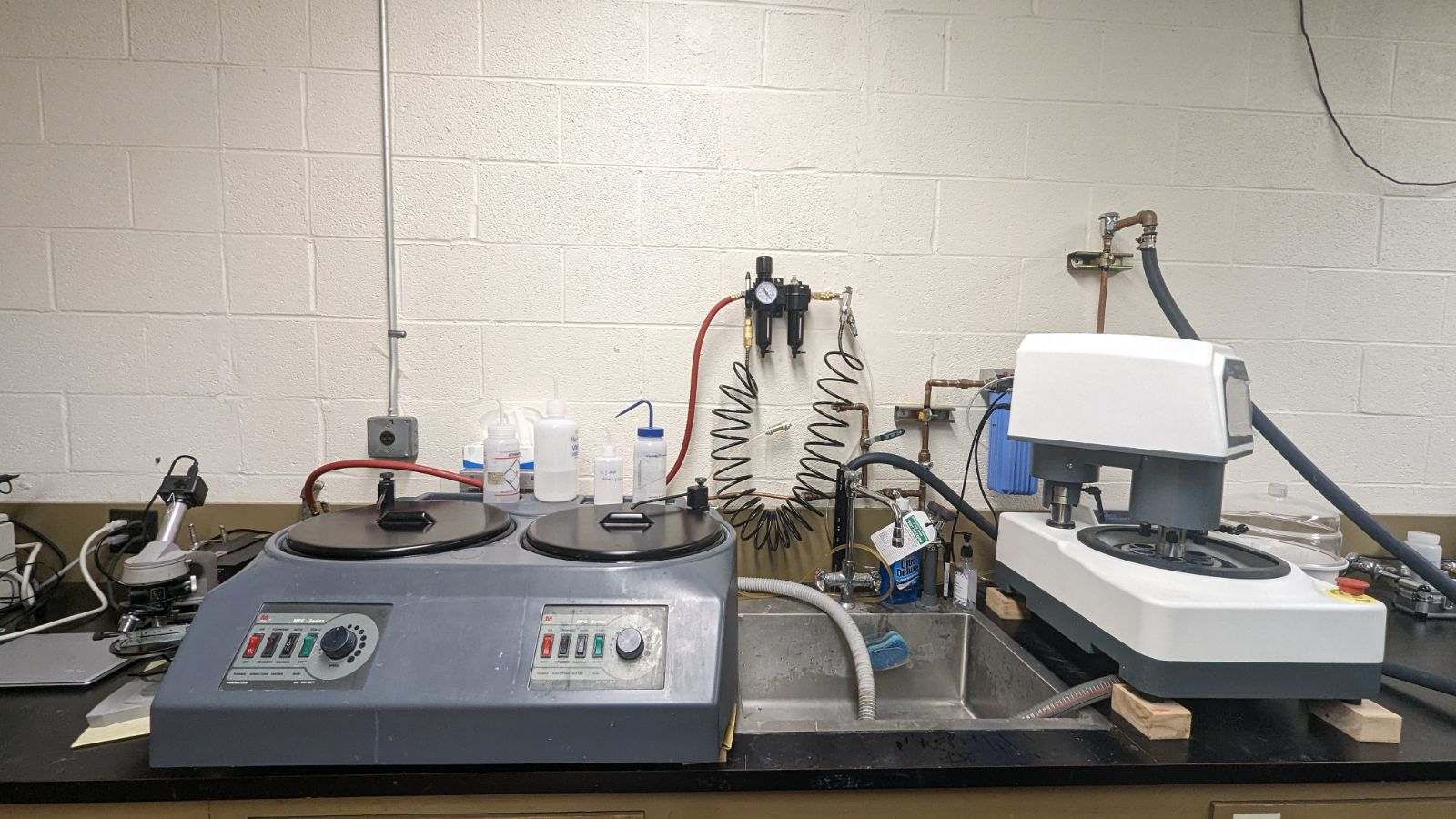

The demand for advanced semiconductor packaging necessitates the use of more robust copper films with fine grains at smaller scales, typically less than 20 µm. However, the characterization of such small and thin samples poses significant challenges. To address this, Kawasaki and Bay have joined forces to enhance capabilities by integrating digital image correlation (DIC) with tensile testing of relatively small samples. Nevertheless, testing thin films pushes the limits of fixtures, crosshead motion, and force measurement.

Our objective is to boost the capabilities of our miniaturized tensile testing facility to test thin metallic films and other small-scale samples accurately and reliably. This will be achieved by incorporating a properly scaled materials test system with suitable performance specifications.

Recent studies demonstrated the applicability of severe metal deformation techniques, which introduce high pressure and mechanical shearing to refine the microstructure of metal composites and greatly increase their strength, but the non-continuous nature of these techniques has been a barrier to scale-up and commercialization. This award supports fundamental research needed for the development of a continuous manufacturing process to produce high strength nanocrystalline sheet metals. This project uses a new cold angular rolling processing (CARP), which employs a single roller for shearing and compressing metals in a continuous process to create layered nanocrystalline sheets. The value of this process comes through efficient bonding and microstructural modification of low-cost sheet metals in a continuous, energy-efficient process.

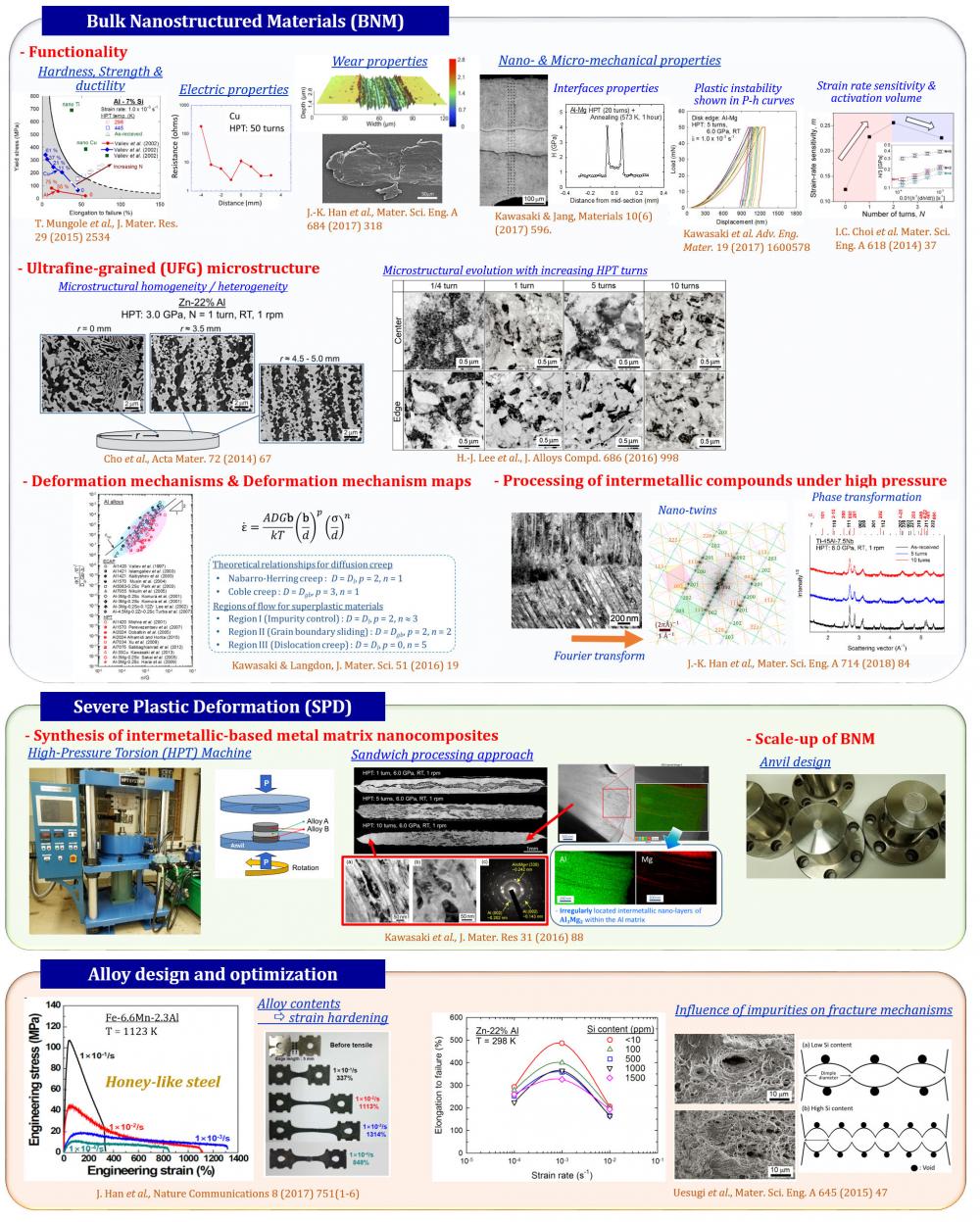

The objectives of this project are to understand the plastic flow mechanisms for strengthening and plasticity in micro- and macro-scales in ultrafine microstructures, and to design strategies to increase both strength and ductility of ultrafine-grained Al systems processed by HPT. This project combines expertise in metallurgical research on nanocrystalline materials with advanced characterization methods of measurements by the novel nanoindentation technique and state-of-the-art X-ray and electron diffraction analysis.

The objectives of this project are two-fold. First, it is to improve the mechanical properties, such as toughness and tensile strength, of aluminum 2099. Second, it is to improve the process by which aluminum 2099 undergoes heat-treatment, making it have desirable properties. This will be accomplished by subjecting samples to severe plastic deformation by HPT.

We would like to express our special thanks to Smiths High Performance who have helped us with the supply of difficult-to-source metal samples including titanium alloys, for our Advanced Materials Processing and Analysis Laboratory.

The objective of this project is to fully characterize ultrafine-grained titanium aluminide (TiAl) processed by the high-pressure torsion technique. With 20-30 nm grain size, such material demonstrates very different mechanical properties and plasticity behavior than with conventional microstructures. The extreme high-pressure torsion process introduces complex plastic shear strain. Not only the grain size has been refined, but the atomic disorder is also introduced, and large intergranular and residual stresses occur as a function of position within the bulk body. By utilizing Quantum Beam Science, we will perform position resolved maps recording the total scattering in order to evaluate crystallographic phase composition, size-strain broadening, atomic disorder, residual hydrostatic pressure, residual stress, crystallographic texture, orientation correlation and strain partitioning between the two phases by orientation resolved peak intensities, peak positions, peak profile and diffuse scattering.

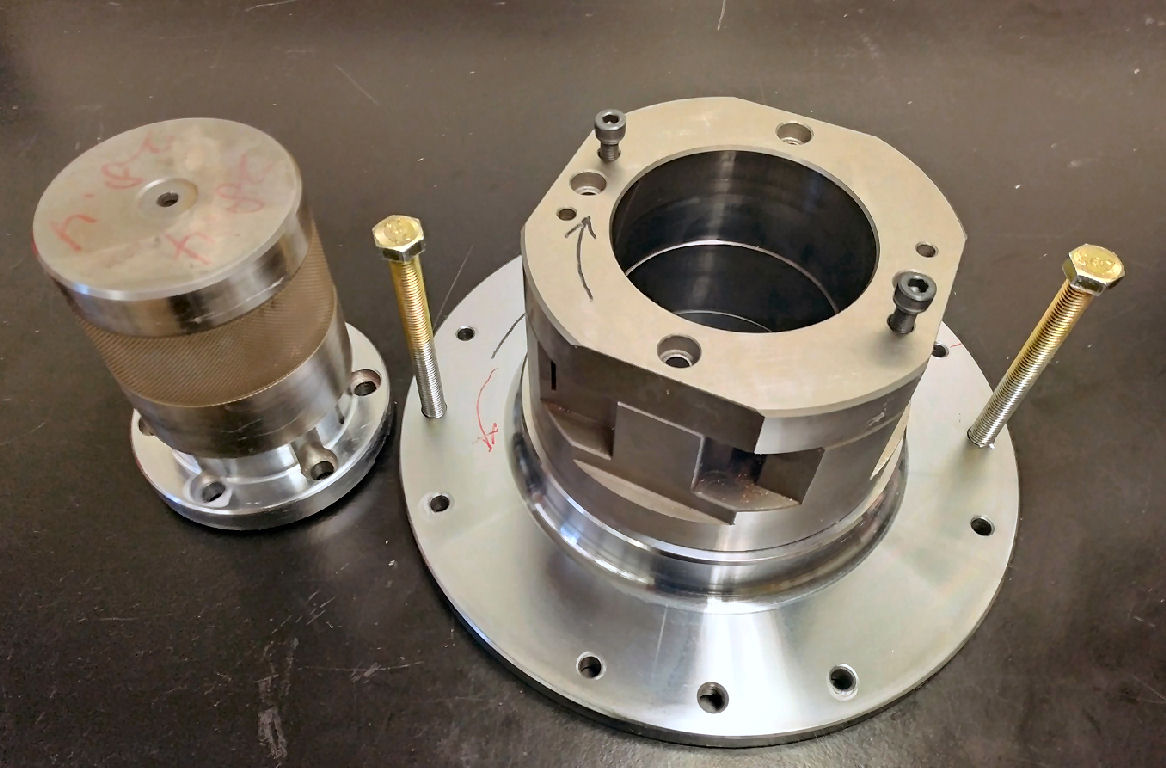

Manufacture: Moinsys, Korea

Press unit: 100 ton

Function: High-temperature processing unit

Manufacture: Moinsys, Korea

-----------------------------------------------------------------------------

Manufacture: TestResources, USA

Load: 10kN

Function: Tensile testing

Two Flir (Point Grey) BlackFly S Monochromator cameras with polarized 25 mm fixed focal length lens.

Custom LabVIEW software to operate the cameras.

Calibration and DIC processing: VIC-3D (Correlated Solutions Inc., Columbia, SC, USA)

-----------------------------------------------------------------------------

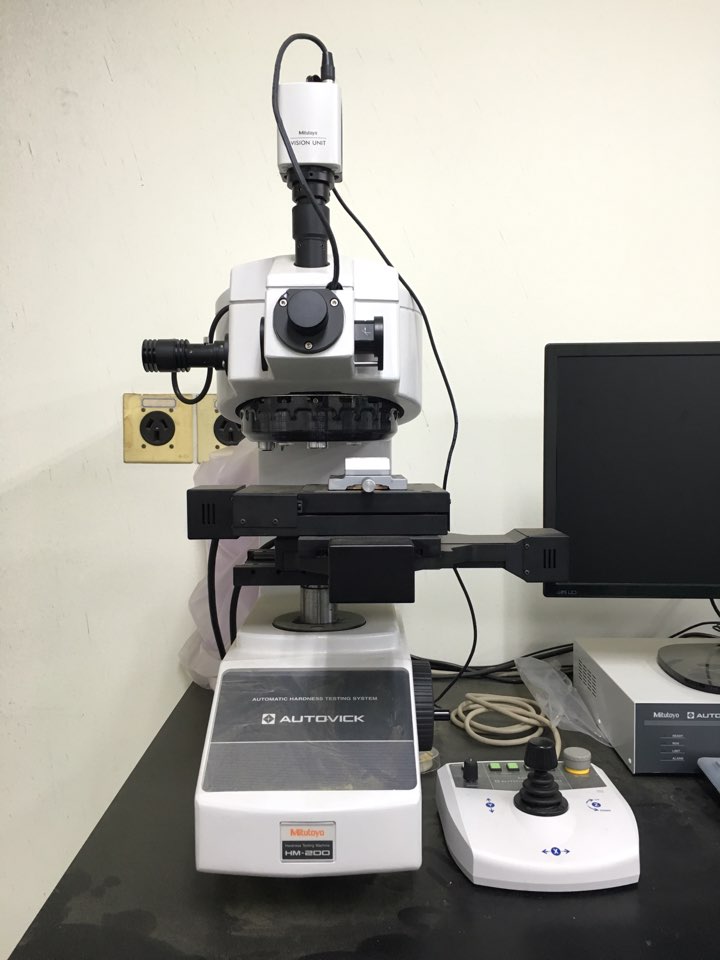

Manufacture: Mitutoyo, Japan

Load: 50gf ~ 2 kgf

Function: Auto focus

-----------------------------------------------------------------------------

Manufacture: Across International

Load: 24 metric tons

Function: pellet for 10 mm diameter peret

-----------------------------------------------------------------------------

Manufacture: Pace Technologies