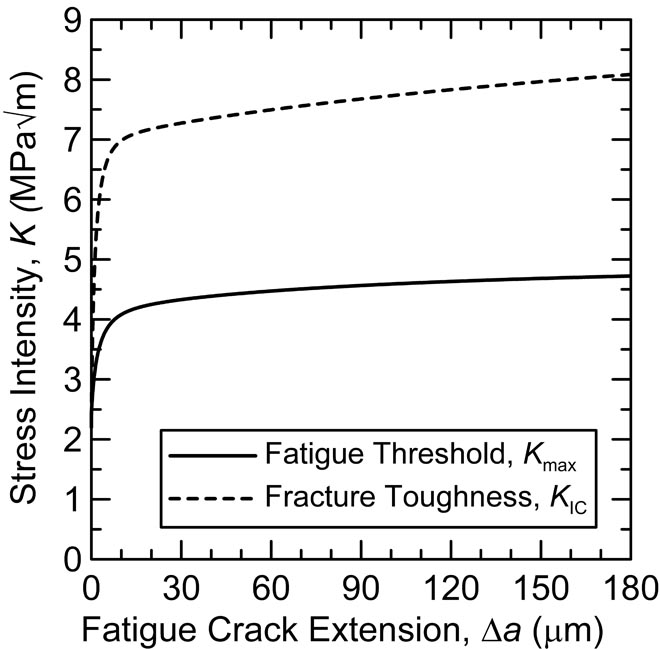

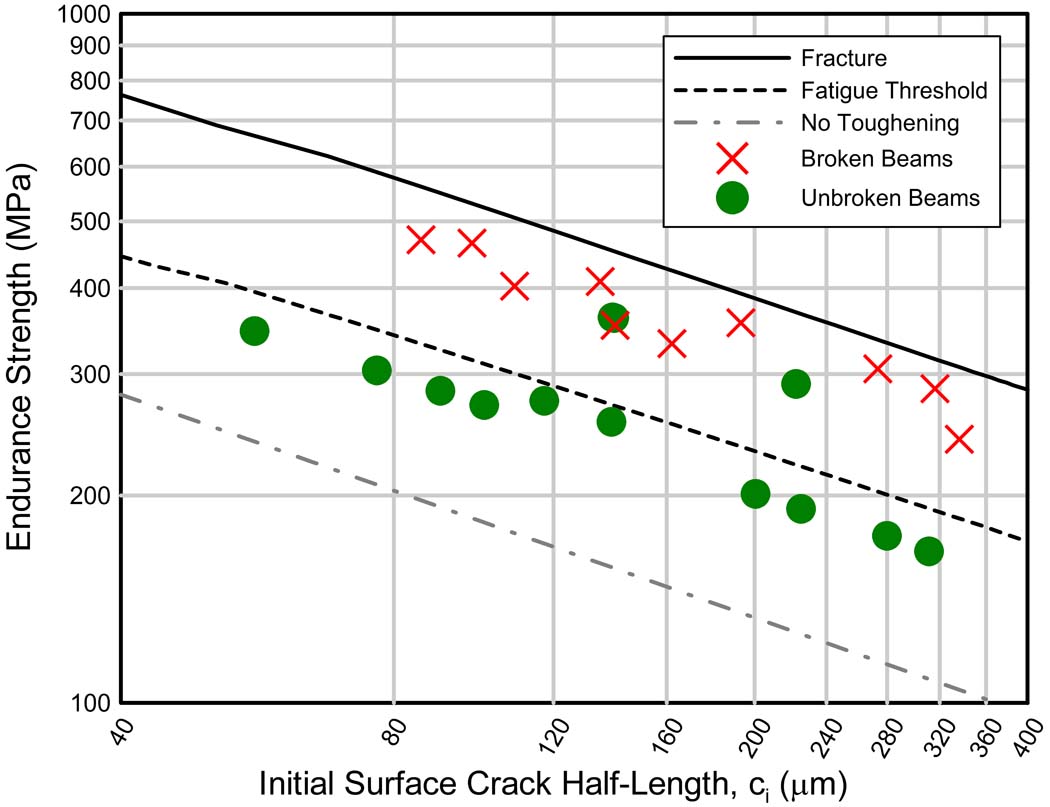

Crack bridging is an effective mechanism for achieving high toughness and strength in many ceramics and composites. However, this mechanism results in a crack size dependence for the fracture properties (R-curve effect) and fatigue properties (small crack effect) when crack sizes are on the order of the bridging zone size. Since brittle materials can only tolerate small crack sizes, making accurate fatigue predictions requires approaches that account for crack size effects. Here it is proposed that fatigue threshold R-curves (Fig. 1) may be used to understand and predict the fatigue behavior of bridging ceramics. In this study, fatigue threshold R-curves are determined for Al2O3 and Si3N4 ceramics and then are used to make fatigue endurance strength predictions for realistic semi-elliptical surface cracks. Furthermore, it is shown that the fatigue threshold R-curve can be determined by quantifying the bridging stress distribution for conventional long crack compact tension specimens without the need for difficult small crack experiments. Also, different methods for determining bridging stress distributions are compared. Finally, it is shown how experimentally measured fatigue data for realistic semi-elliptical surface cracks agrees well with predictions based on quantitative bridging zone characterization (Fig. 2). Overall, it is expected that this methodology will be extendable to cover a wide range of materials toughened by crack bridging, including ceramics, intermetallics, composites, and biological materials.

This research was funded by the National Science Foundation.