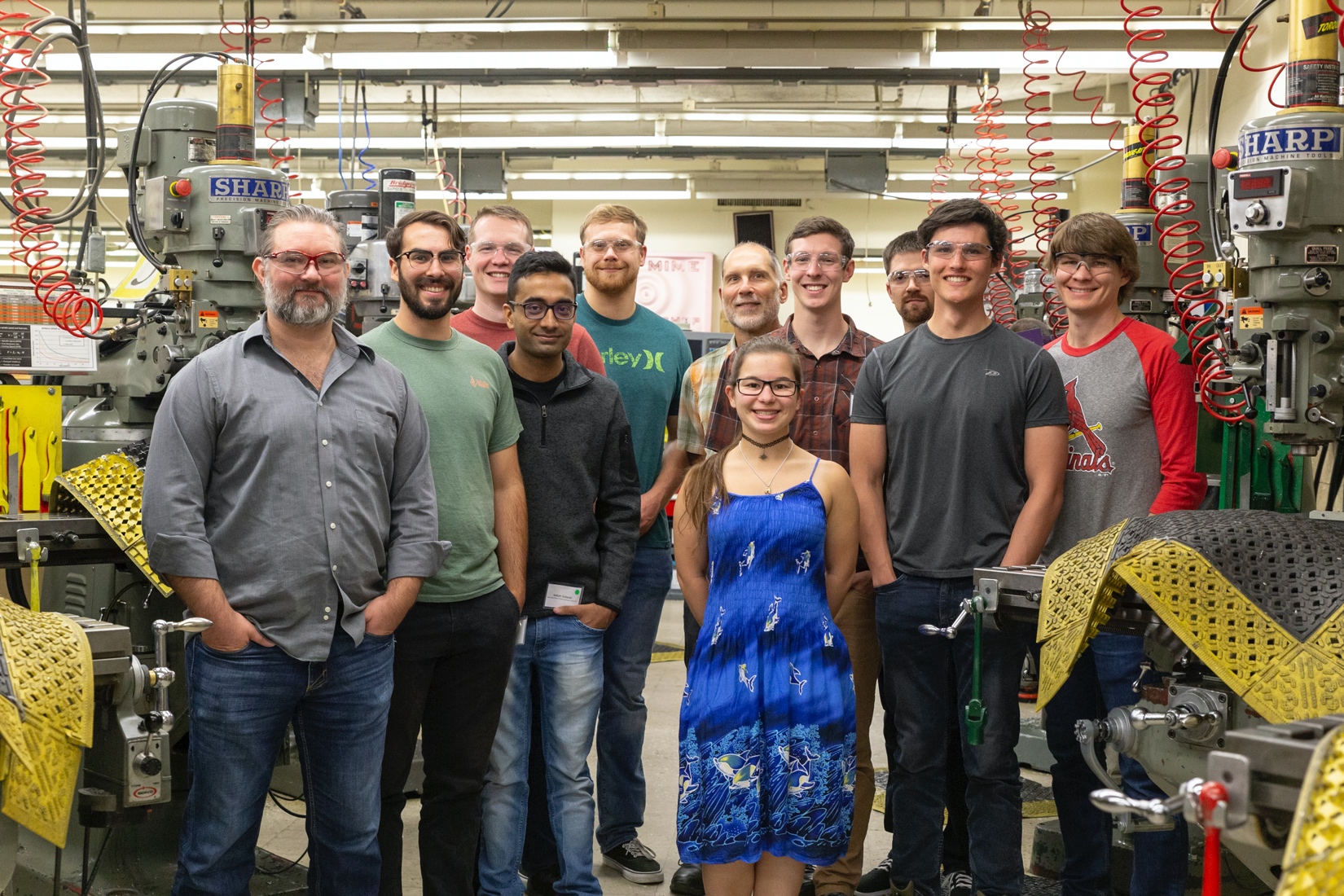

The Prototype Development Lab (PDL) is located in the College of Engineering at Oregon State University. The focus of the PDL is to create new and novel prototype products by interacting with industry and entrepreneurs and to provide outstanding experiential learning for students. The PDL solves real world problems and delivers results having practical bottom-line value.

Prof. John Parmigiani is the leader of the PDL. He has a life-long passion for the creation of mechanical devices, extensive practical experience and academic training, and is uniquely positioned at OSU to guide the PDL. His technical expertise is supplemented, as needed, by the technical expertise of other OSU faculty.

PDL students and faculty engineer, design, and build mechanical, and electromechanical devices and create software for startups, established companies, and university researchers. The PDL uses cutting-edge technology, additive manufacturing techniques (e.g. 3D printing), and digital- manufacturing equipment and software to efficiently design and build prototypes. These prototypes can be custom equipment or a new product for an industry client or a first demonstration of a market-worthy idea or the improvement of an existing prototype for an entrepreneur. For industry the PDL provides an extension to in-house engineering capability to add capacity and expertise. For entrepreneurs the PDL provides a means of obtaining a functioning physical embodiment to attract investors, obtain patents, create a product, and move to mass manufacturing and sales.

The PDL has extensive resources available for device fabrication. Of particular significance are the Machining and Product Realization Lab (MPRL) and Oregon Manufacturing Innovation Center (OMIC). The MPRL is located in Corvallis, OR and is part of OSU. The mission of the MPRL is “to help students develop the practical side of their engineering skill set as they complete their undergraduate or graduate program”. To this end the MPRL contains considerable fabrication equipment. The PDL has access to all MPRL equipment including:

OMIC is located in Scappoose, OR and is an industry consortium focused on applied metals research. The mission of OMIC is to “Develop and apply advanced metals manufacturing technologies and processes for industrial competitive advantage and academic growth, while inspiring and educating the next generation’s manufacturing workforce”. Correspondingly OMIC contains the latest metal fabrication and metrology equipment. The PDL has access to all OMIC equipment including:

The PDL also has access to many other research facilities at OSU. For example: the OSU Electron Microscopy Facility, the OSU Composites Materials Manufacturing Lab, and the OSU Materials Characterization Lab.

John Parmigiani has a life-long love of mechanical engineering. Academic training began with metals-machining and vehicle mechanics courses prior to college and was followed with B.S. and M.S. degrees in mechanical engineering from the Pennsylvania State University, and a Ph.D in mechanical engineering from the University of Michigan. Professional experience includes 10 years as a practicing engineer in industry with several Pennsylvania manufacturing firms. Personal experince includes vehicle repair & restoration and countless construction & repair projects on his Pennsylvania farm and Oregon home. His current work at Oregon State University focuses on providing useful solutions to real-world engineering problems for a wide variety of project sponsors.

Licensed Professional Engineer in Oregon, Pennsylvania, and Washington

PhD in Mechanical Engineering, University of Michigan, 2007

MS in Mechanical Engineering, The Pennsylvania State University, 1997

BS in Mechanical Engineering, The Pennsylvania State University, 1987

Director of the Prototype Development Lab

Research Associate Professor of Mechanical Engineering

Director of Industry Research for the School of Mechanical, Industrial, and Manufacturing Engineering

Capstone Coordinator for the School of Mechanical, Industrial, and Manufacturing Engineering