Project description

https://agsci-labs.oregonstate.edu/sfpp/

https://daimler-trucksnorthamerica.com

PDL mechanical engineering students

By the conclusion of the six-month project with the PDL the company, Lora DiCarlo Inc, was launched. The company won CES innovation awards in 2019 and 2020 for products initiated with the PDL.

The project and associated 2019 CES award were the topic of a New York Times article

PDL graduate student Jacob Porter

PDL graduate student Dakota Pellegrino and PDL undergraduates Nicole LeRoux), Matt Sessions, and David Foyil.

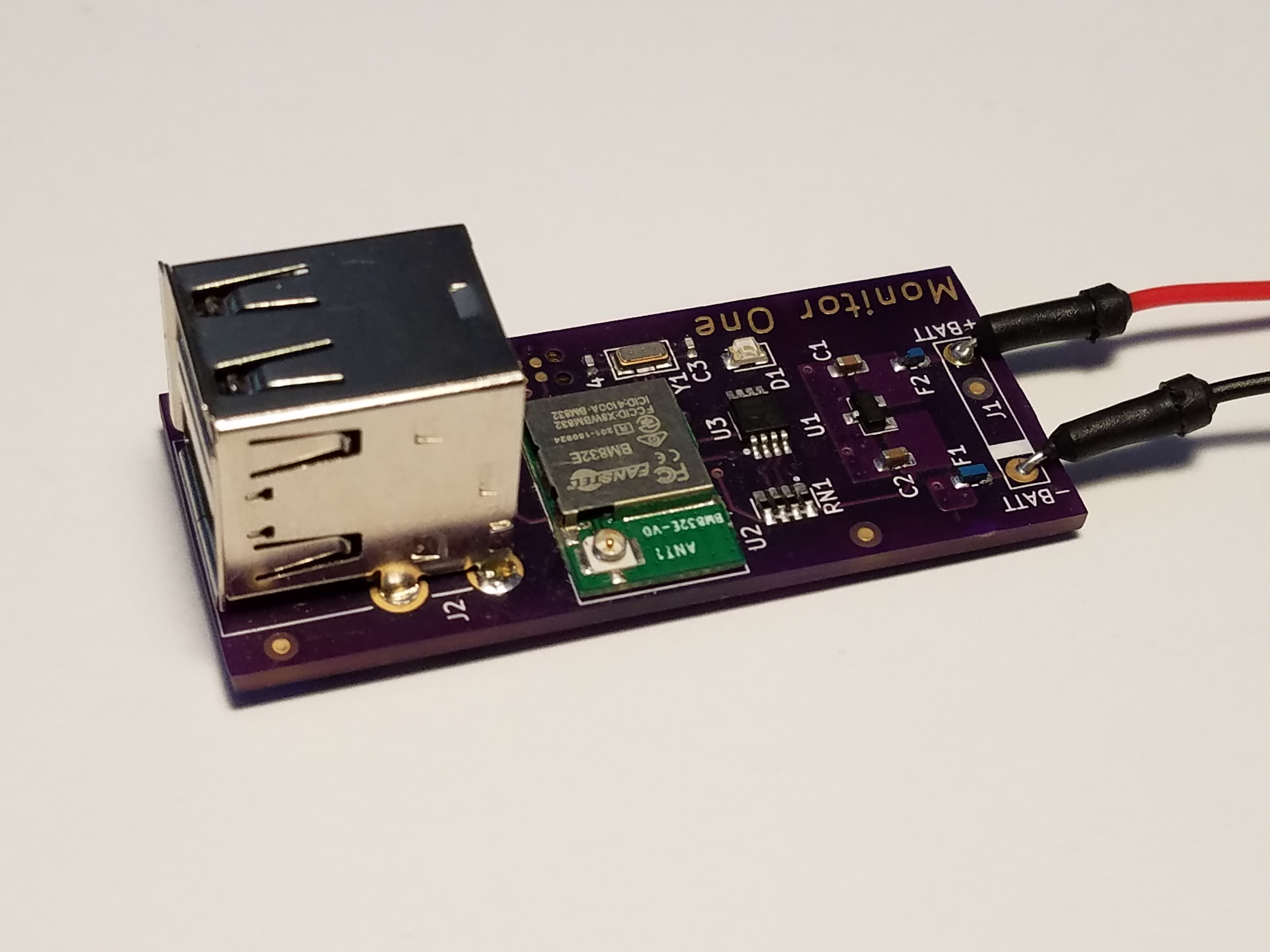

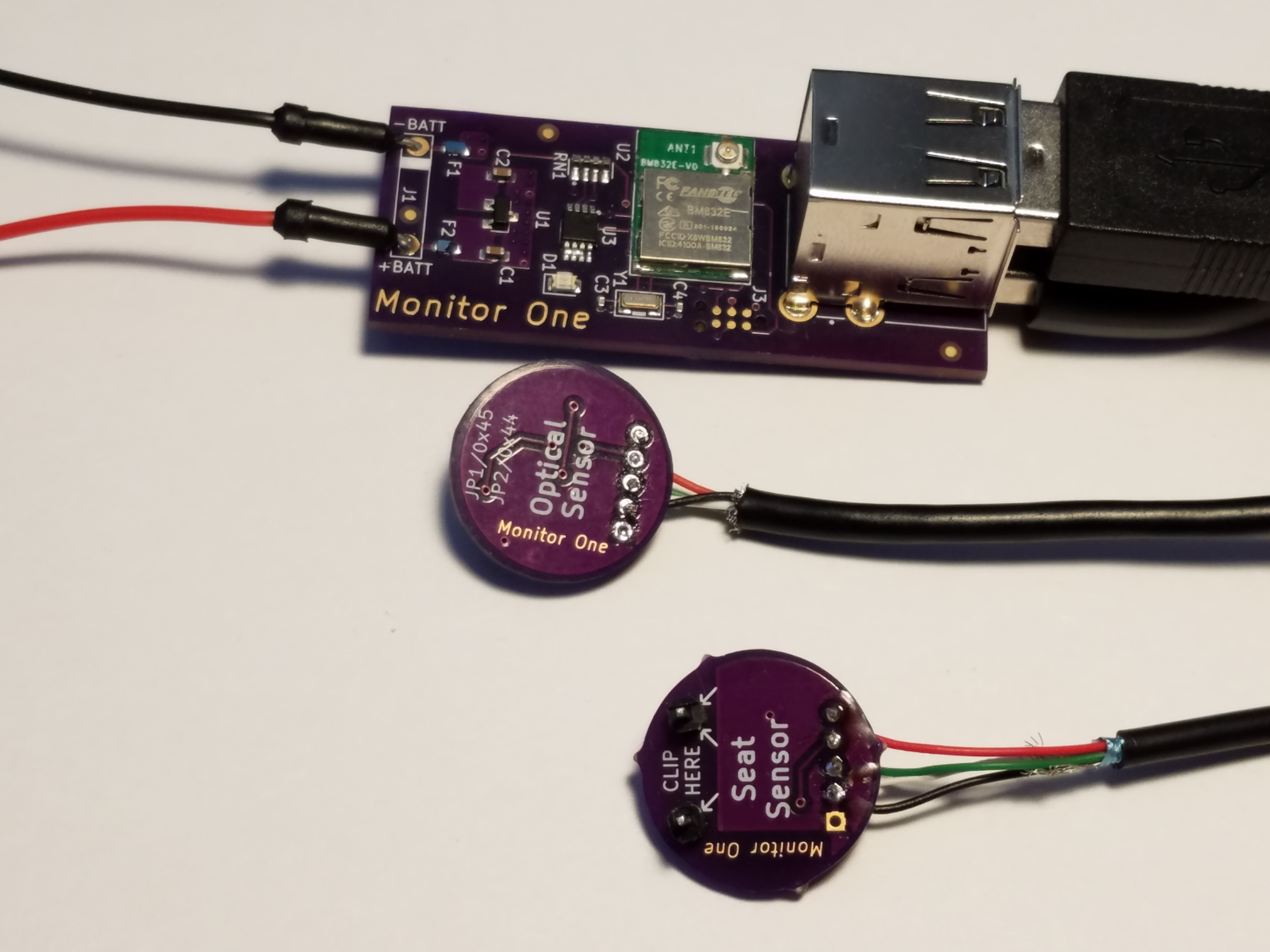

A year-long project led to a functioning prototype with associated software and the launch of the company.

PDL graduate students Mark McGuire and Eric Shannon and a number of PDL undergraduate students.

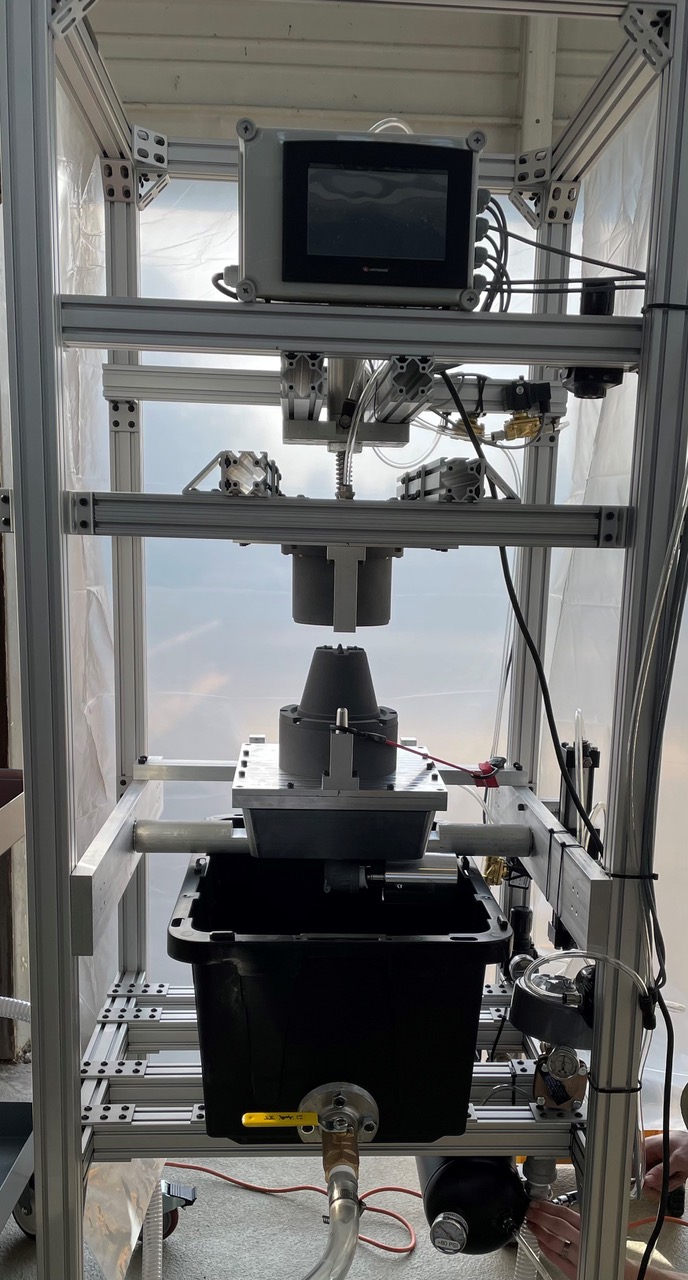

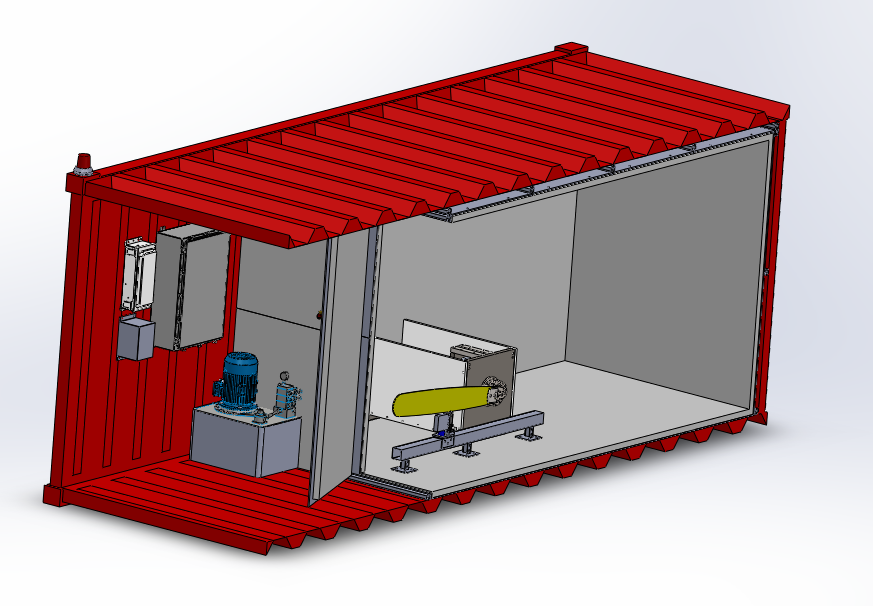

A two-year project resulted in fully-functioning test apparatus being delivered to Blount’s Oregon facility. The apparatus was built inside a shipping container lined with steel plate and HDPE panels to insure safe projectile capture. The apparatus is currently being used by Blount Inc.

PDL undergraduates Matt Sessions, Nicole LeRoux, and David Foyil and PDL graduate student Dakota Pellegrino.

A year-long project led to a functioning prototype with associated software and the launch of the company

PDL graduate student Nick Aerne

The system was successfully validated and has been implemented commercially.

PDL undergraduate Kinsey Popham

Two fully-functioning prototypes were created. PeeBall was licensed immediately following project completion and is commercially available. Shucket is under consideration by a major retailer. Based on this success, a follow-up project involving other Oliiv patented concepts is underway staffed by PDL undergraduate students Kinsey Popham, Matt Sessions, and Allison Van Horn.

PDL Graduate Students Kevan Gahan and Jacob Porter.

A fully-functioning prototype was delivered.