|

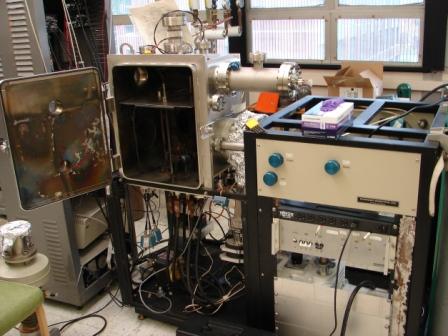

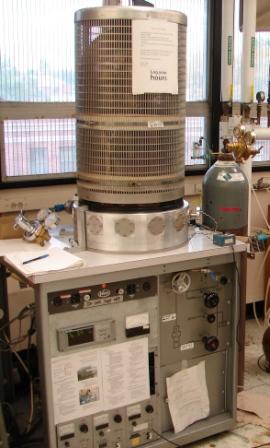

This system incorporates electron beam, sputter and thermal deposition in one chamber. An 8kW, six pocket rotary egun is used primarily for deposition of refractory metals. Two 2” magnetrons are available for sputter deposition of chalcogenide materials. In addition, the system is equipped with one thermal evaporation source. The six inch substrate stage has heating to 850C, rotation, RF biasing and in situ adjustment of the source to substrate distance. The system is load locked, and the chamber base pressure is <5e-8 Torr. Process gas is Argon.

|