(Internal and external services of alloy fabrication, casting, vacuum/UHP-Ar encapsulation, and in-situ/ex-situ micro-tensile/compressive tests are provided; contact us for details)

(Our customers have included other OSU research groups, Allegheny Technologies Incorporated, Lam Research Corporation, Leidos, National Energy Technology Laboratory)

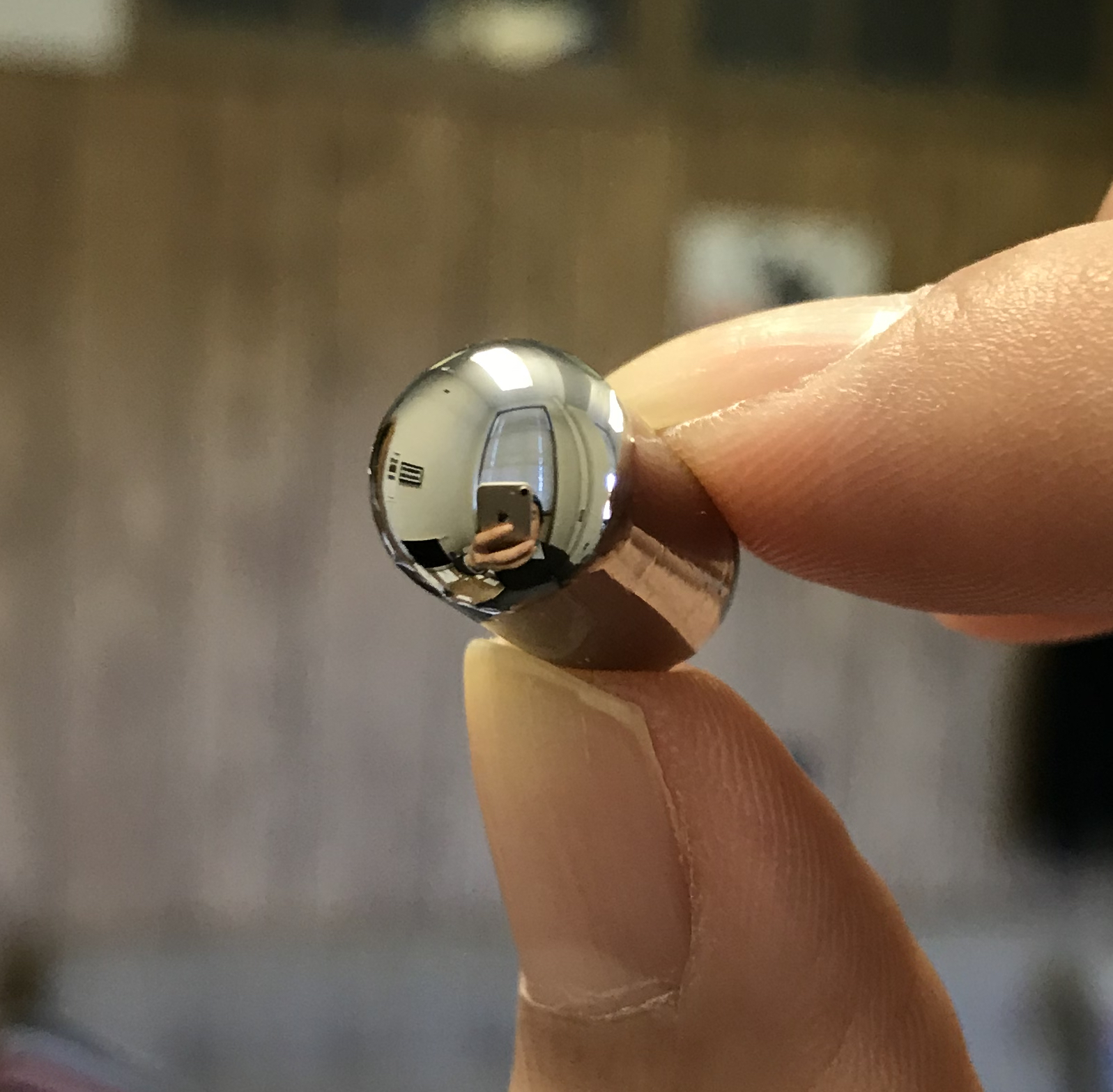

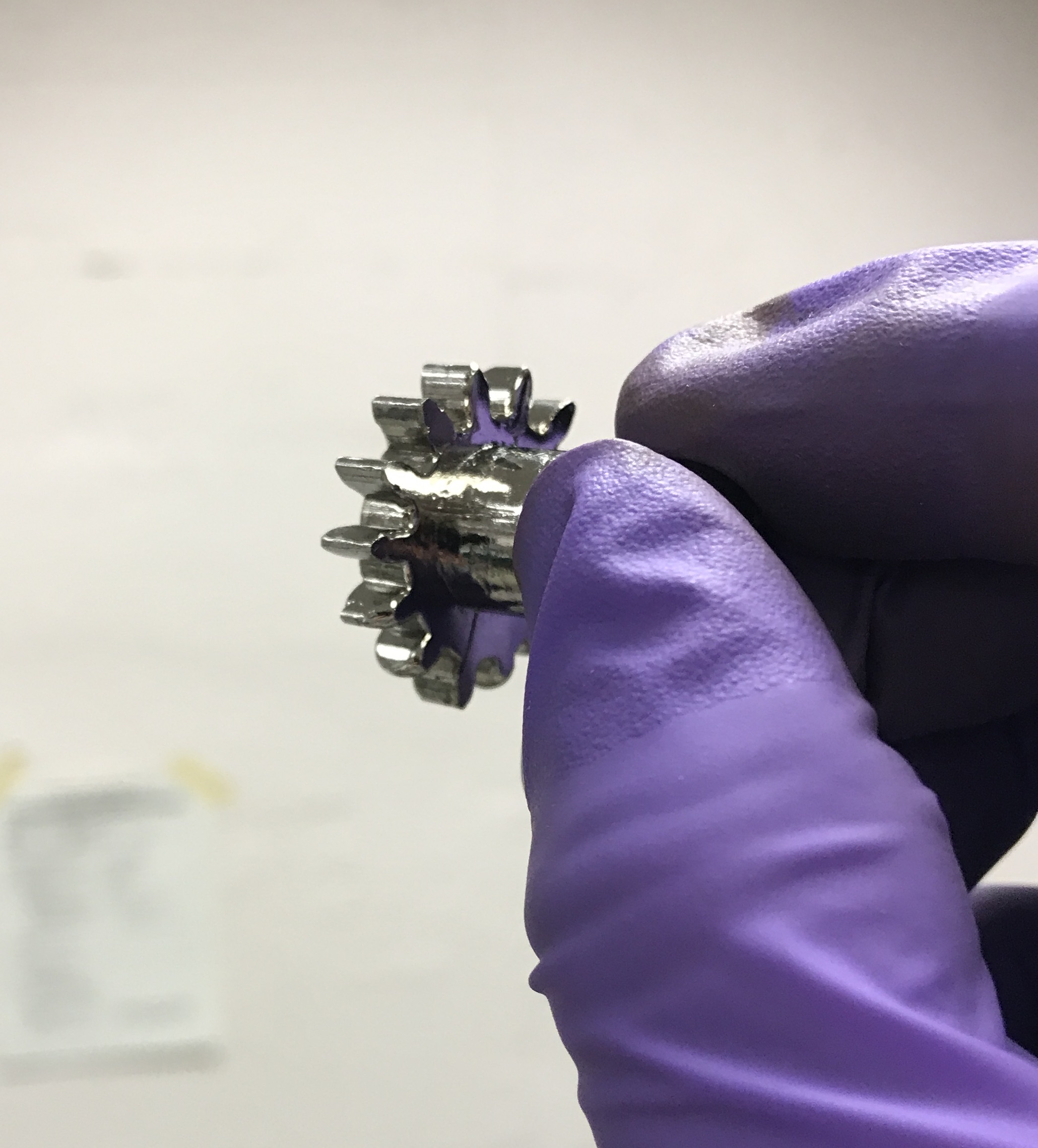

1. Small vacuum arc melter: fabricate metallic samples (up to 25 g) of any composition

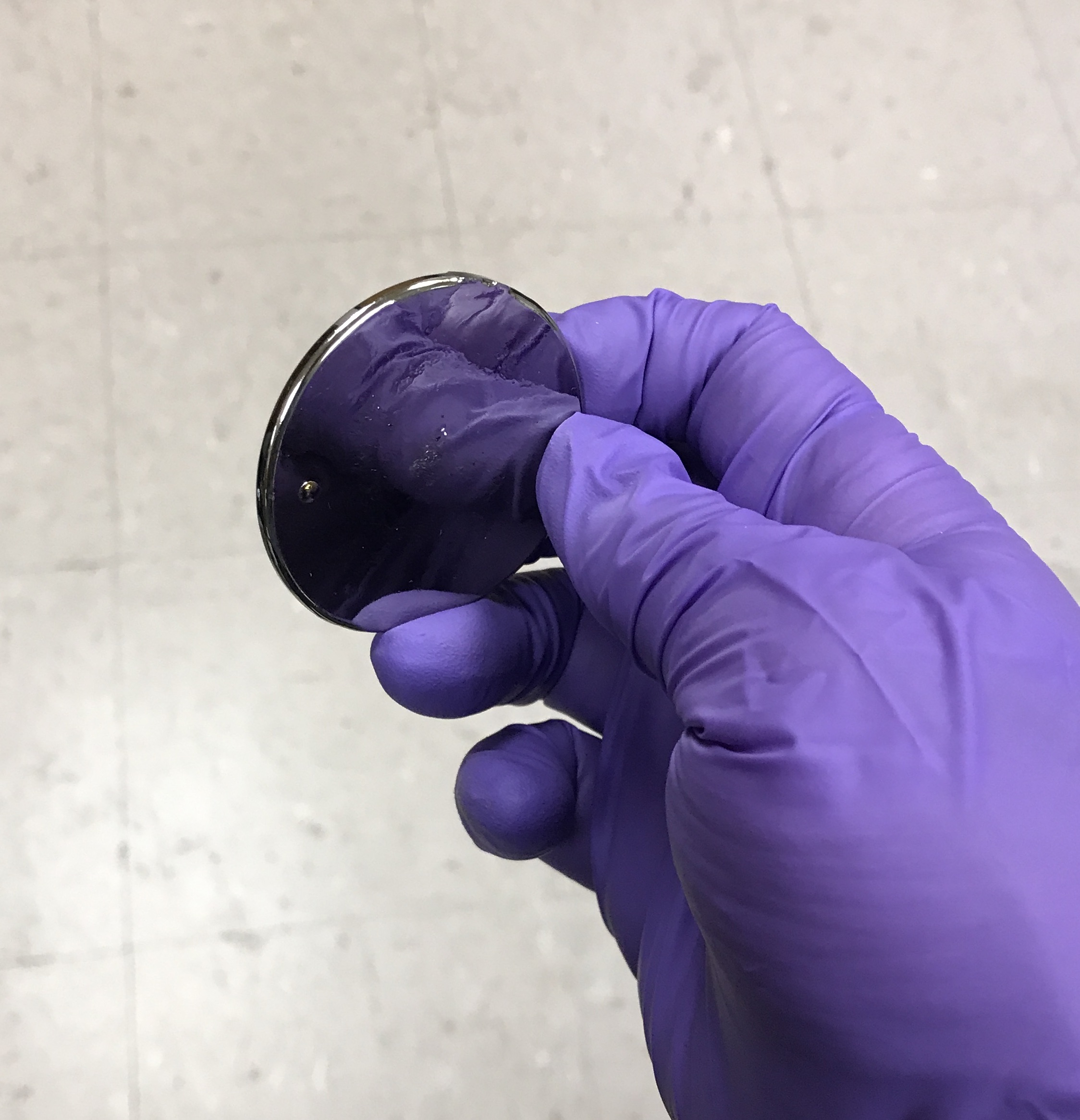

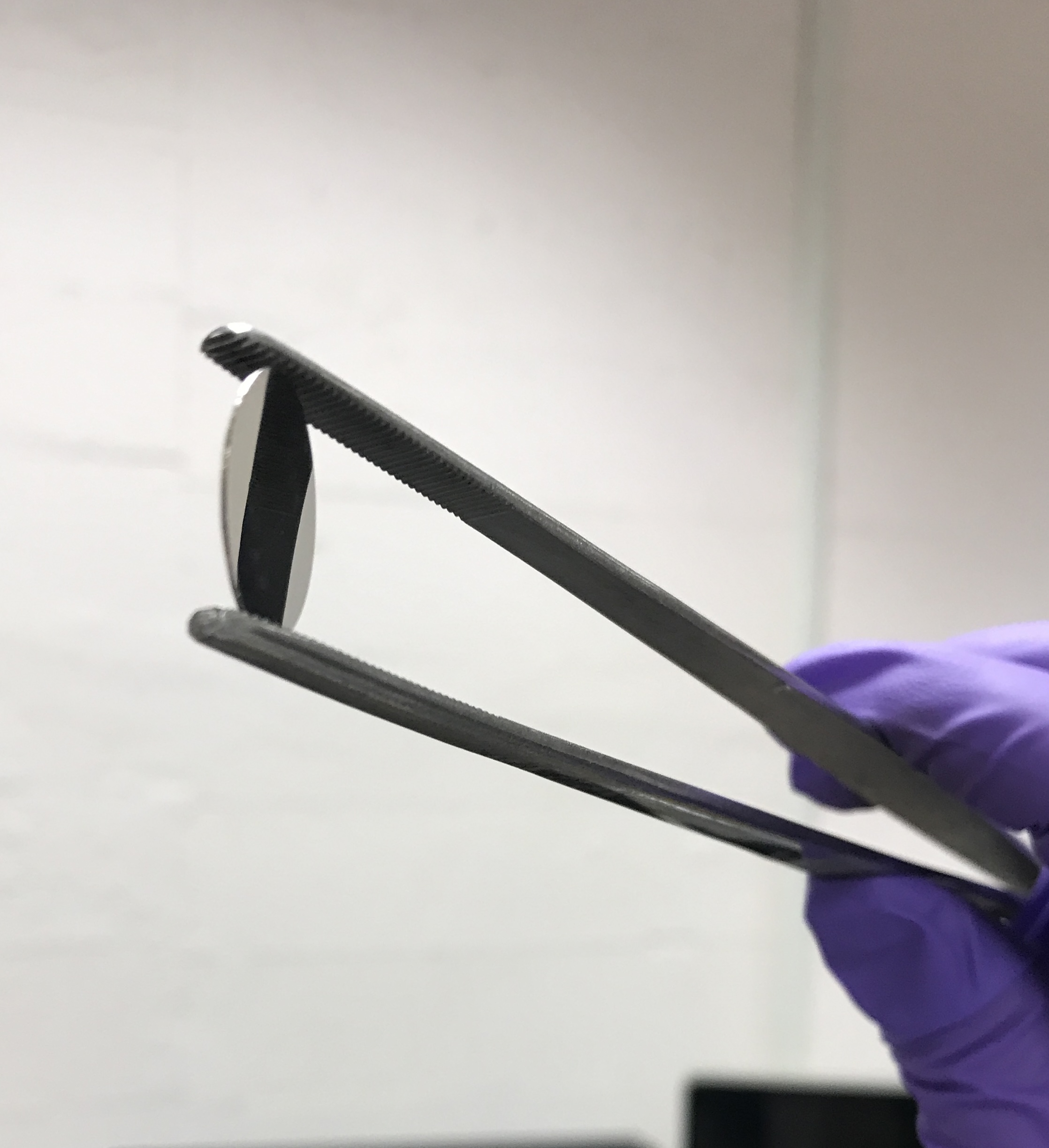

2. Large integrated vacuum arc melting & casting (tilt casting and suction casting) system: fabricate and cast metallic samples (up to 200 g) of any composition; fabricate 1'' diameter alloy sputtering target

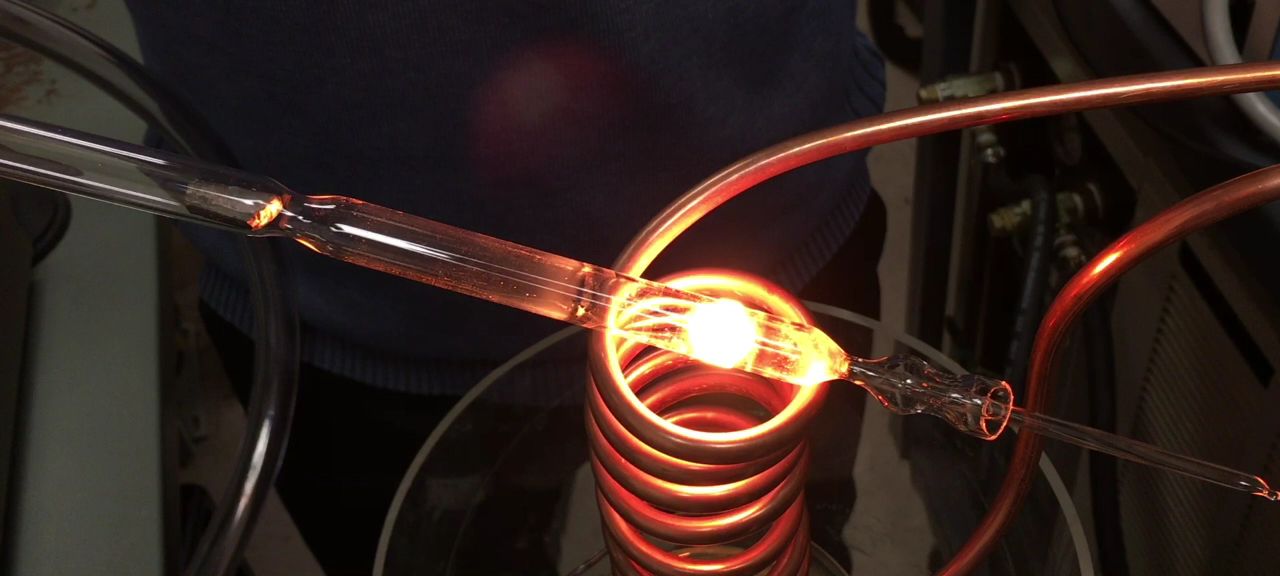

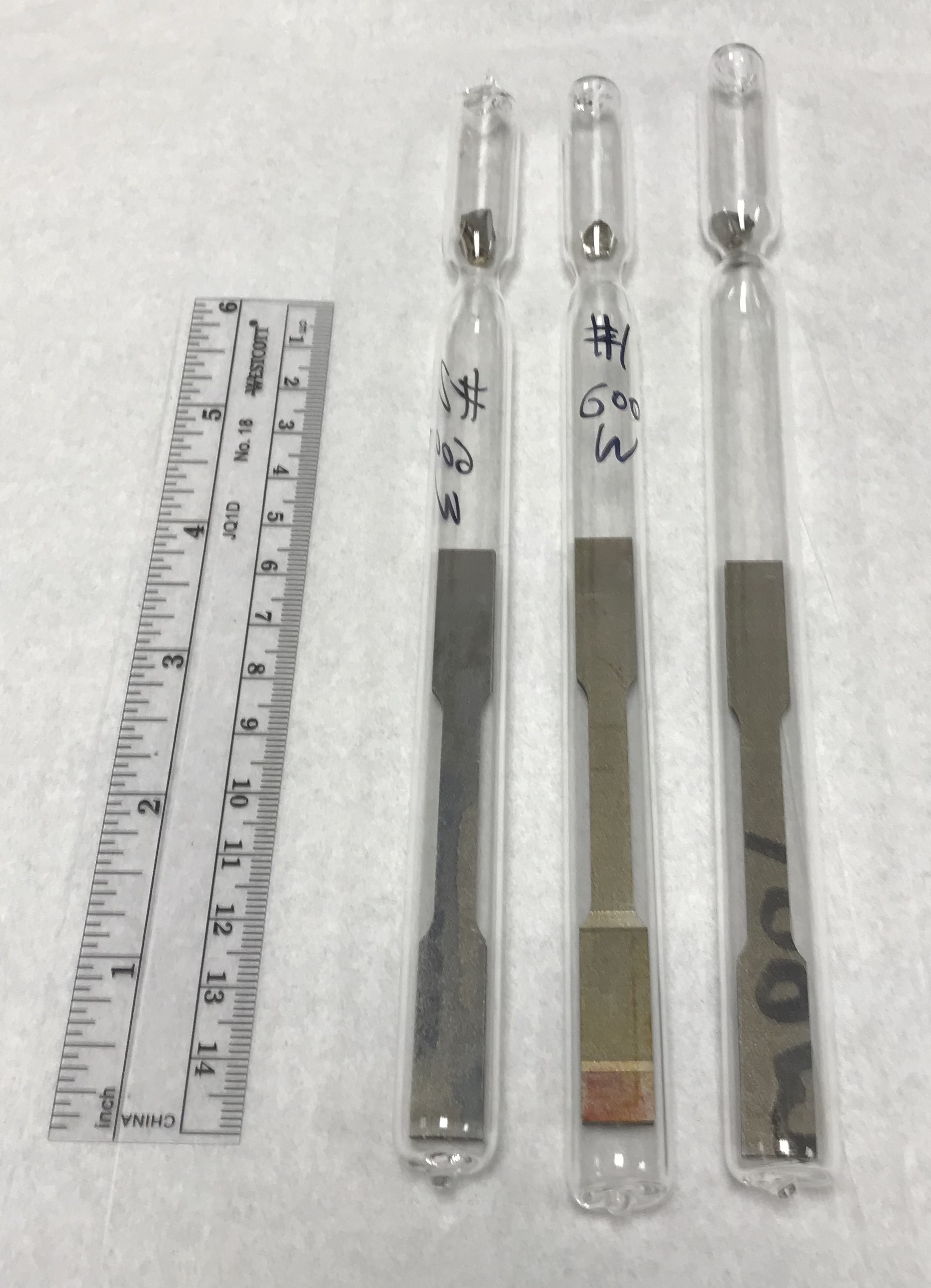

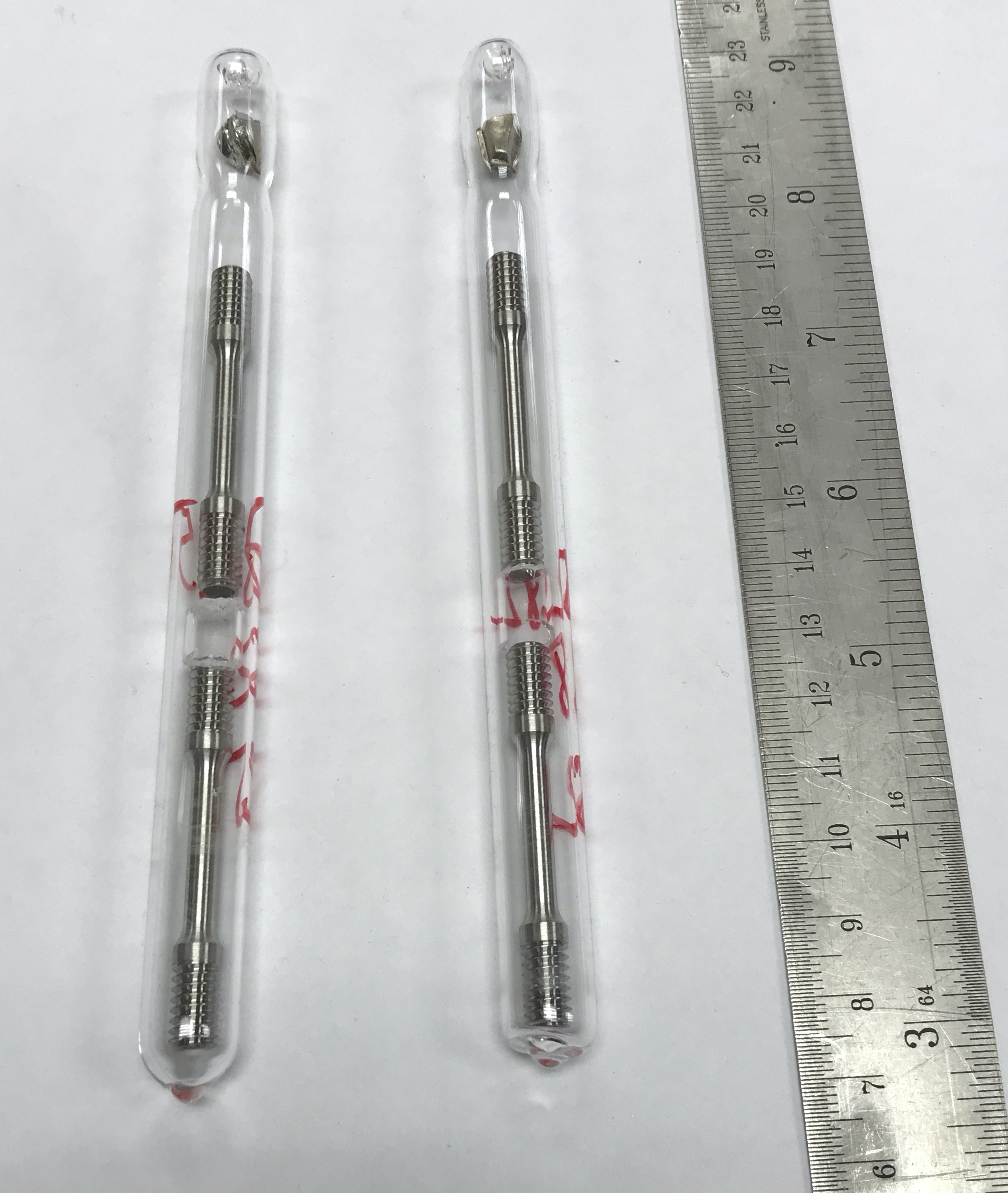

3. Induction melting system: fabricate and/or cast metallic samples (sealed in a quartz tube under vacuum or argon), with options of natural air cooling, water quenching or vacuum injection casting for solidification

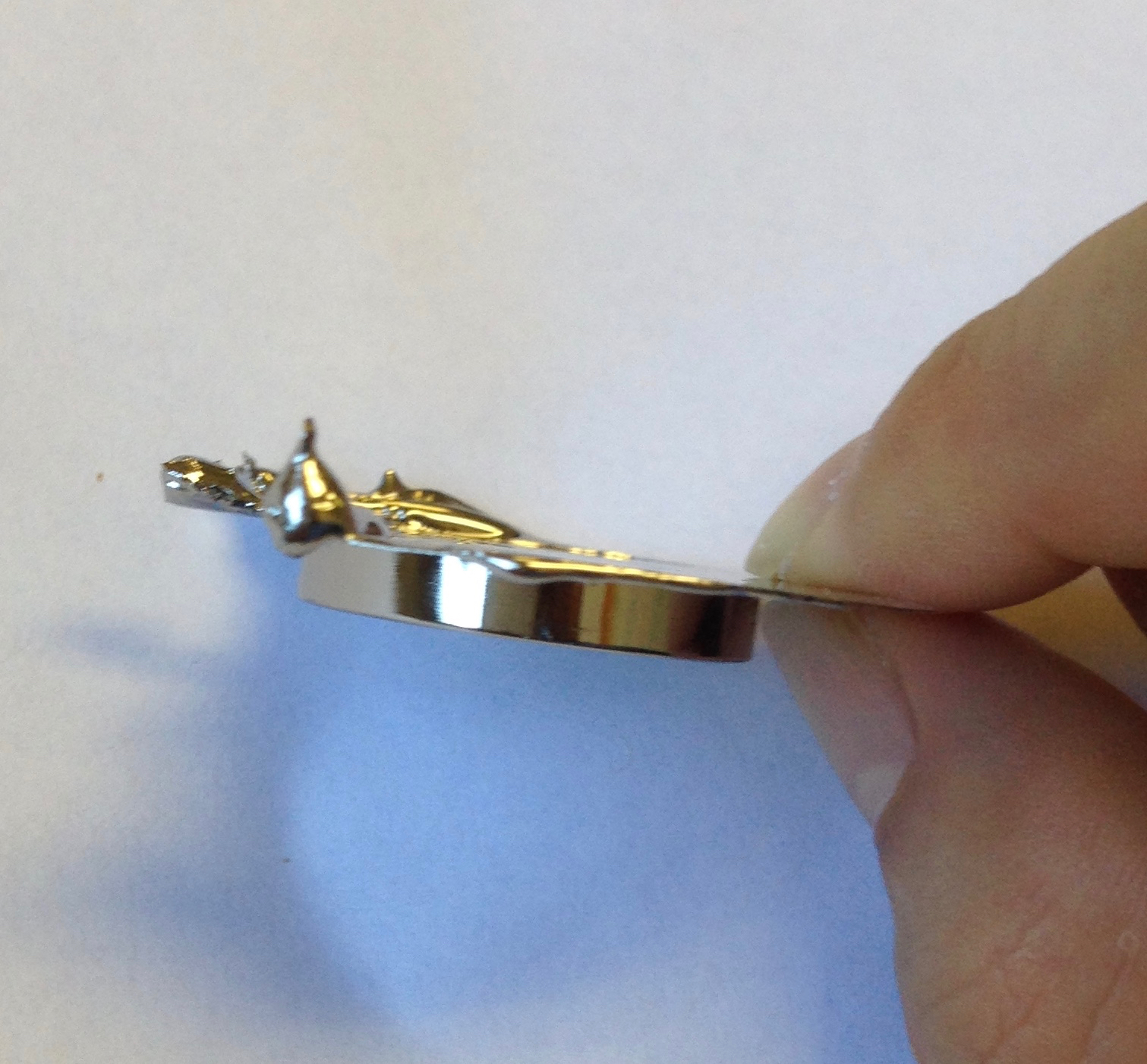

4. Glass blowing system: seal samples in a quartz tube with vacuum or argon inside, for annealing/heat-treatment, melting, rapid quenching and/or injection casting

5. Precision sectioning saw: sample sectioning, all materials

6. Differential scanning calorimeter - Mettler Toledo DSC 3: thermal analysis; determining characteristic temperatures, enthalpy, etc.

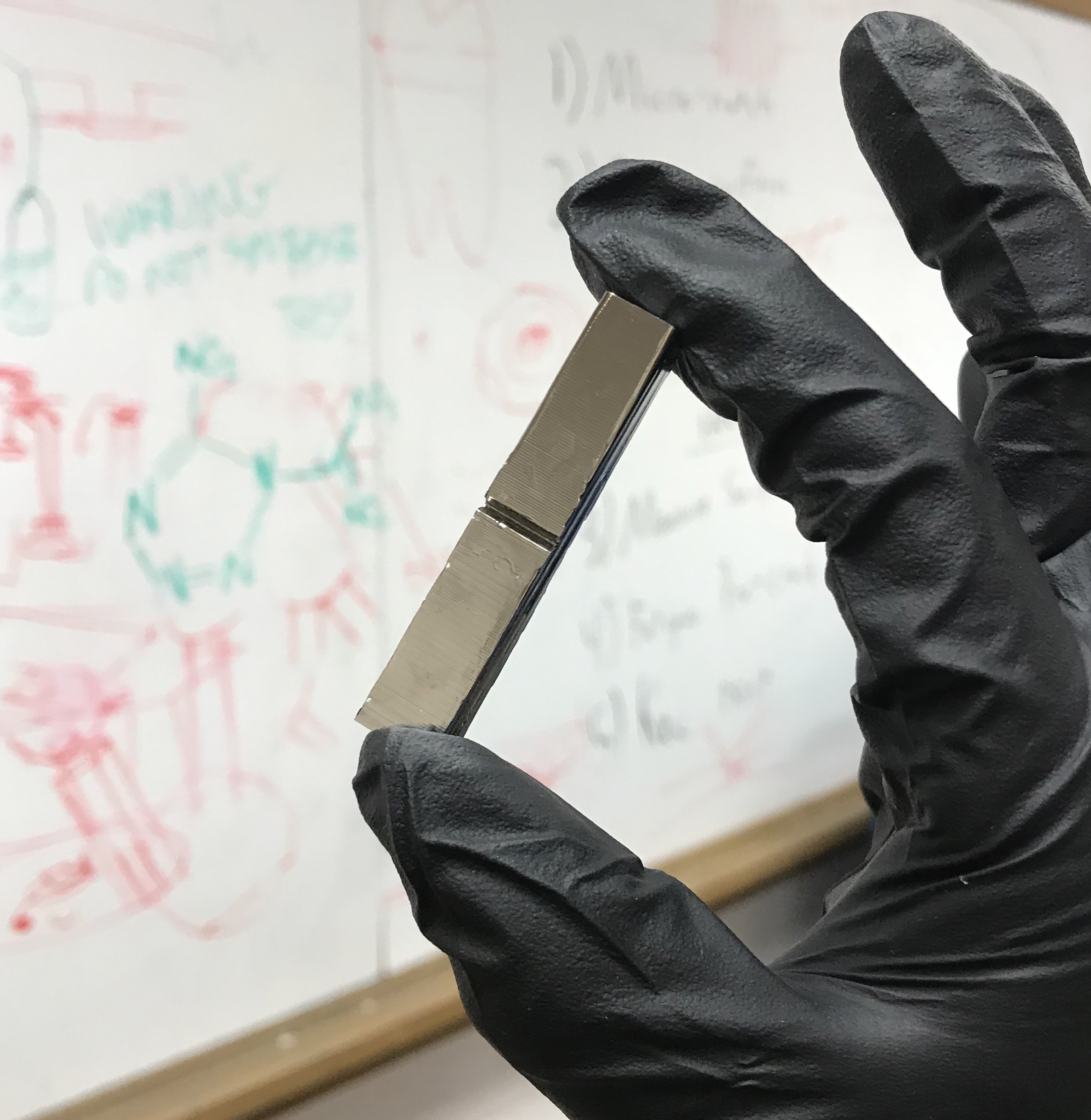

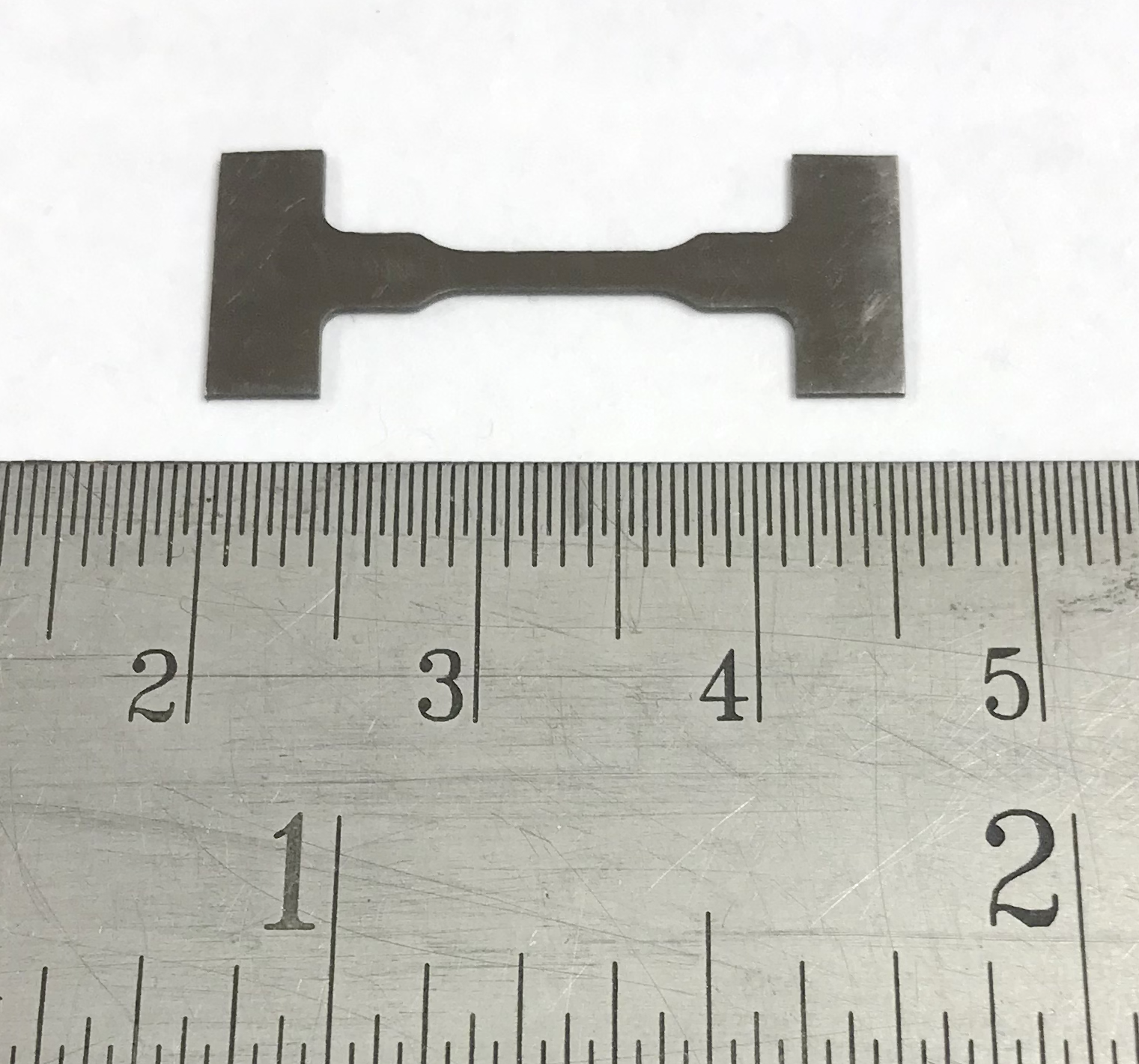

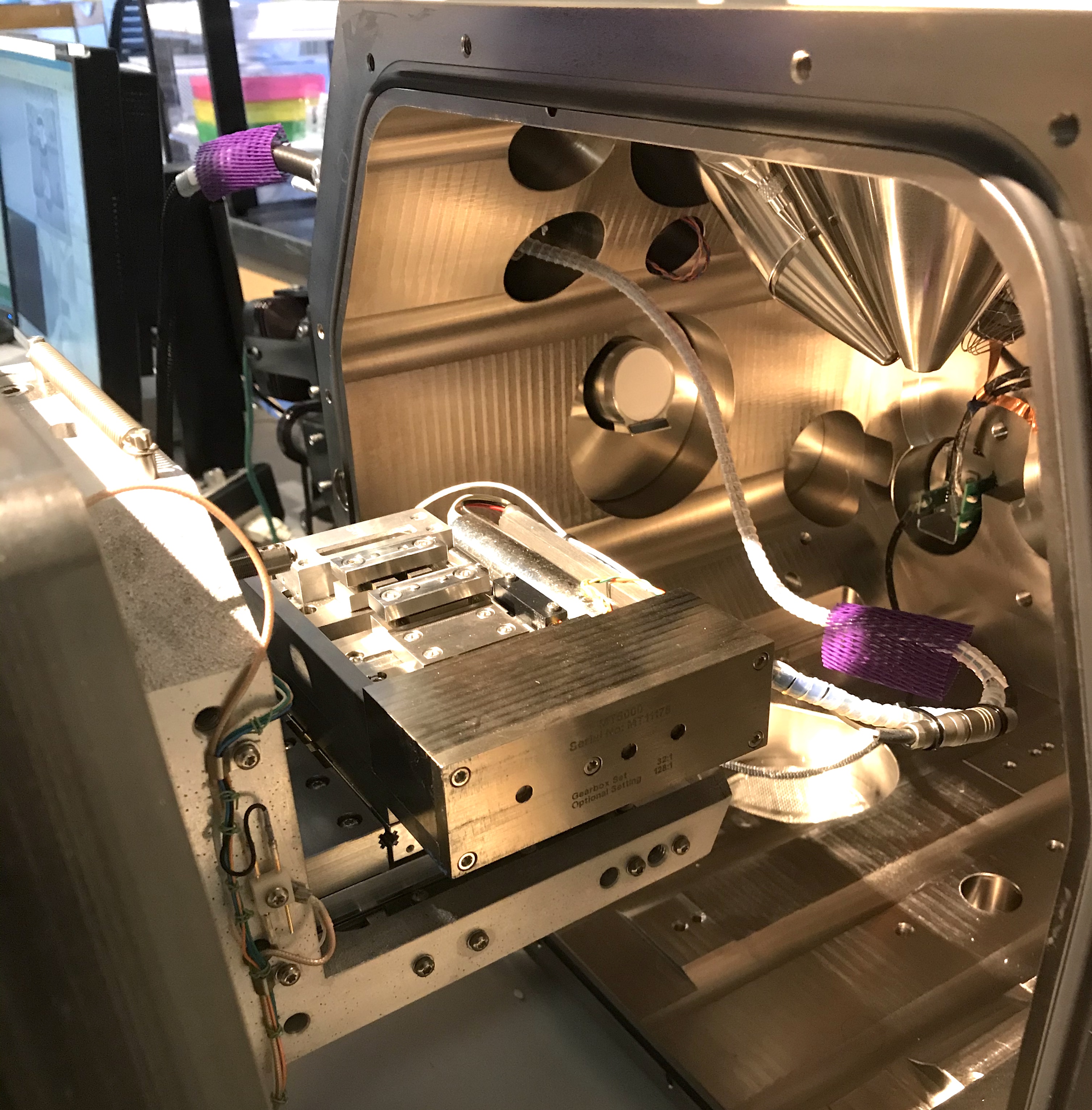

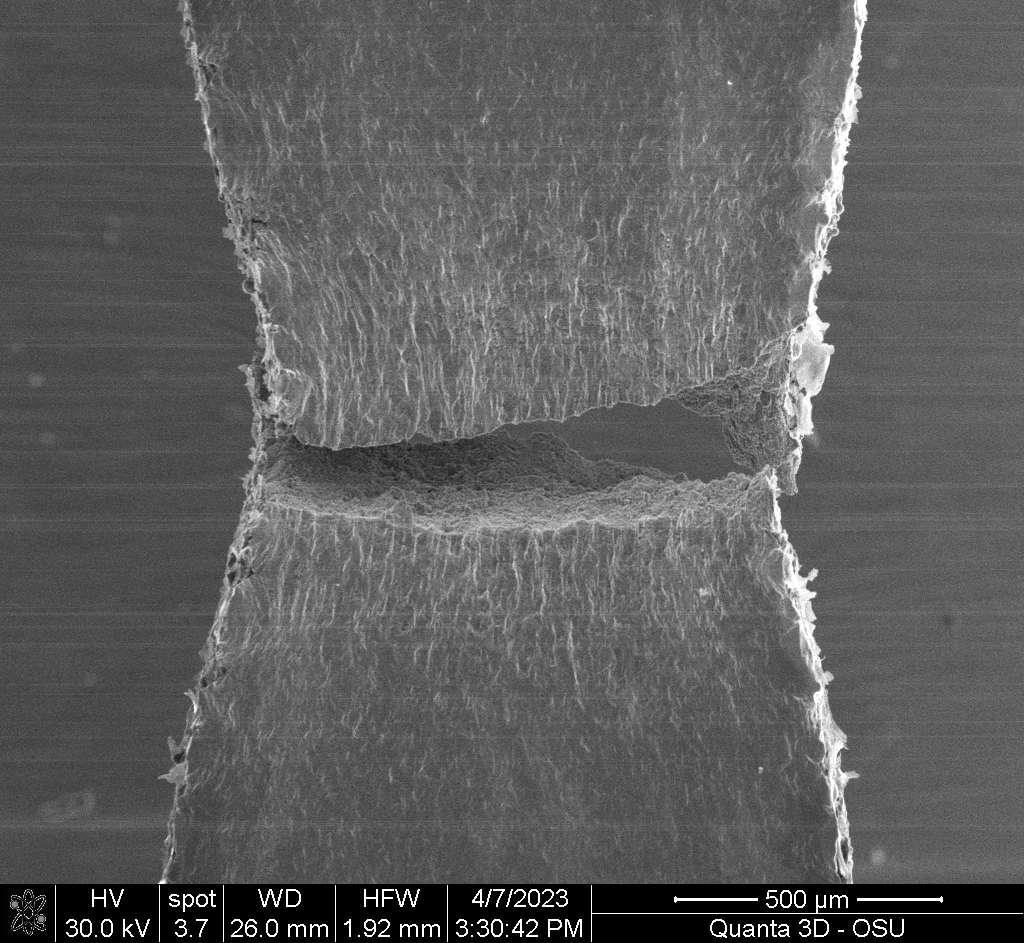

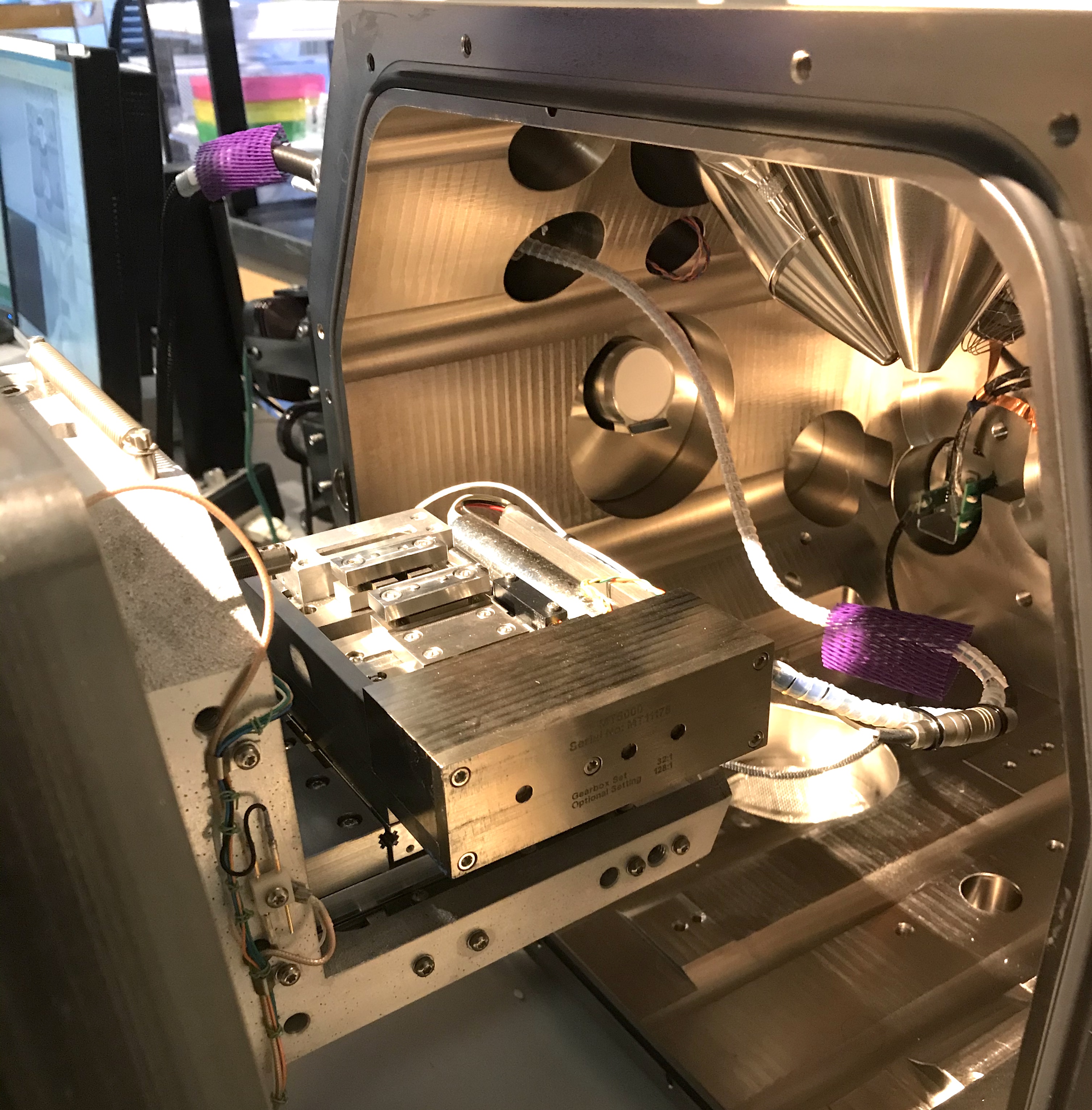

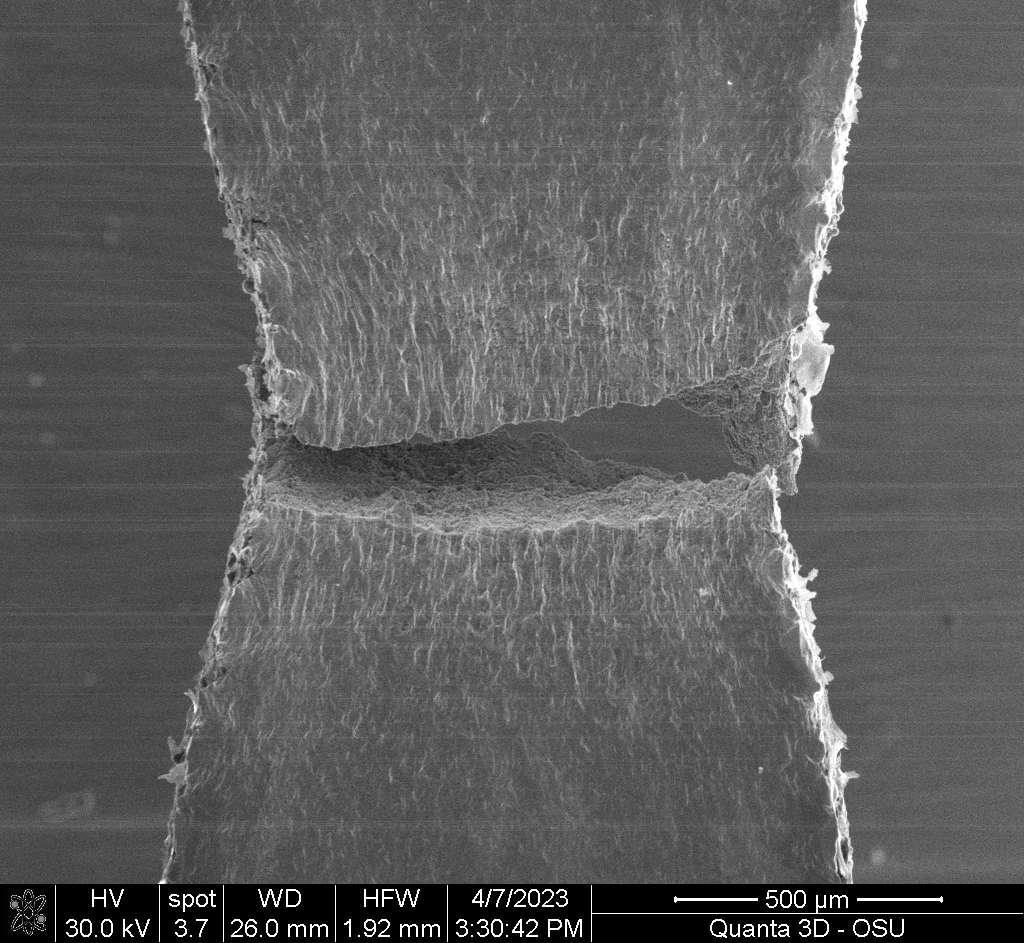

7. In-situ SEM or synchrotron mechanical test module - Deben MT5000: tensile/compressive tests with in-situ microstructure characterization; max load 5000 N.

8. Other materials characterization and testing facilities available at OSU through collaboration or user fees (not a full list):

XRD; SEM; TEM; EDX; FIB; AFM; Vickers hardness tester; nano-indenter; high-T DSC/TGA; Instron testing frames