The Industrial Sustainability Lab aims to assist engineering decision makers in efficiently meeting consumer needs, while not causing harm to people or the planet.

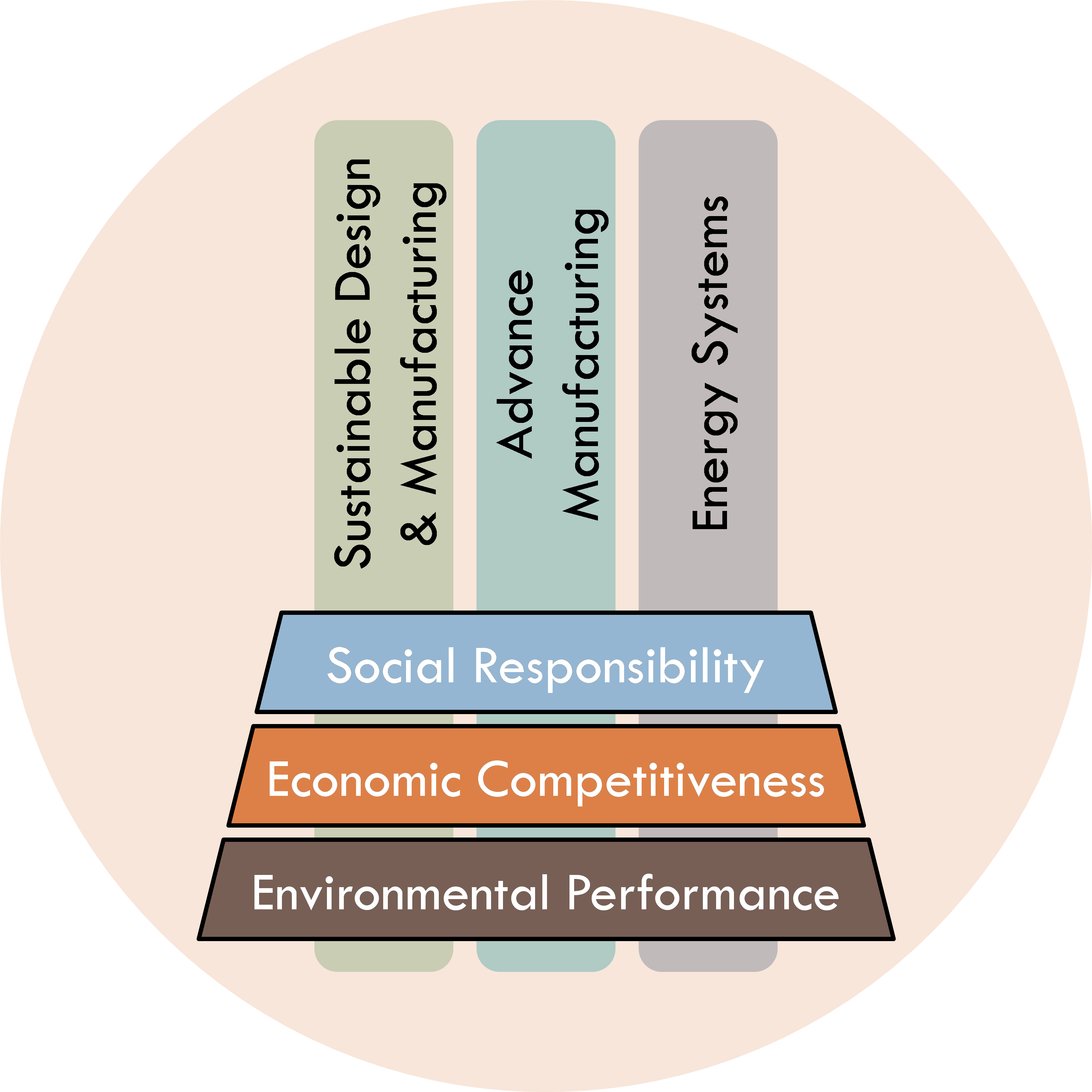

The key research directions and contributions of the ISL can be categorized under the following three thrusts:

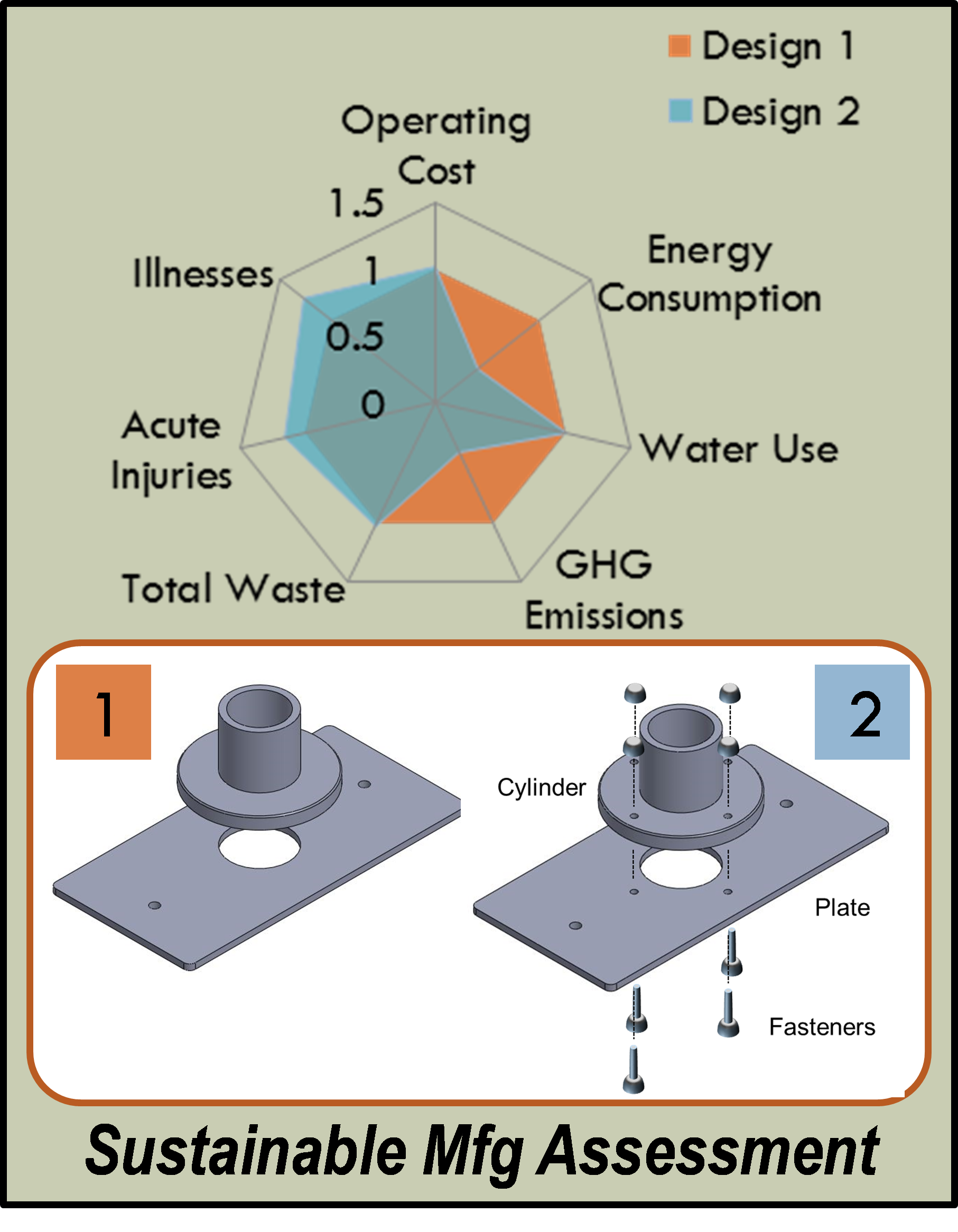

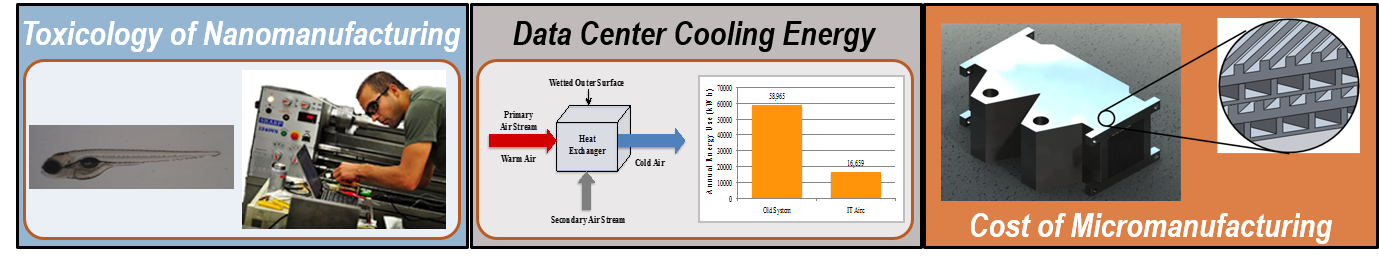

Thrust 1. Sustainable Design and Manufacturing: This research thrust aims to advance design methods and tools to improve product economic, environmental, and social performance, simultaneously, as described below:

Thrust 2. Advanced Manufacturing: Methods developed under Thrust 1 can be extended via direct applications in fundamental research into the following novel manufacturing processes and systems:

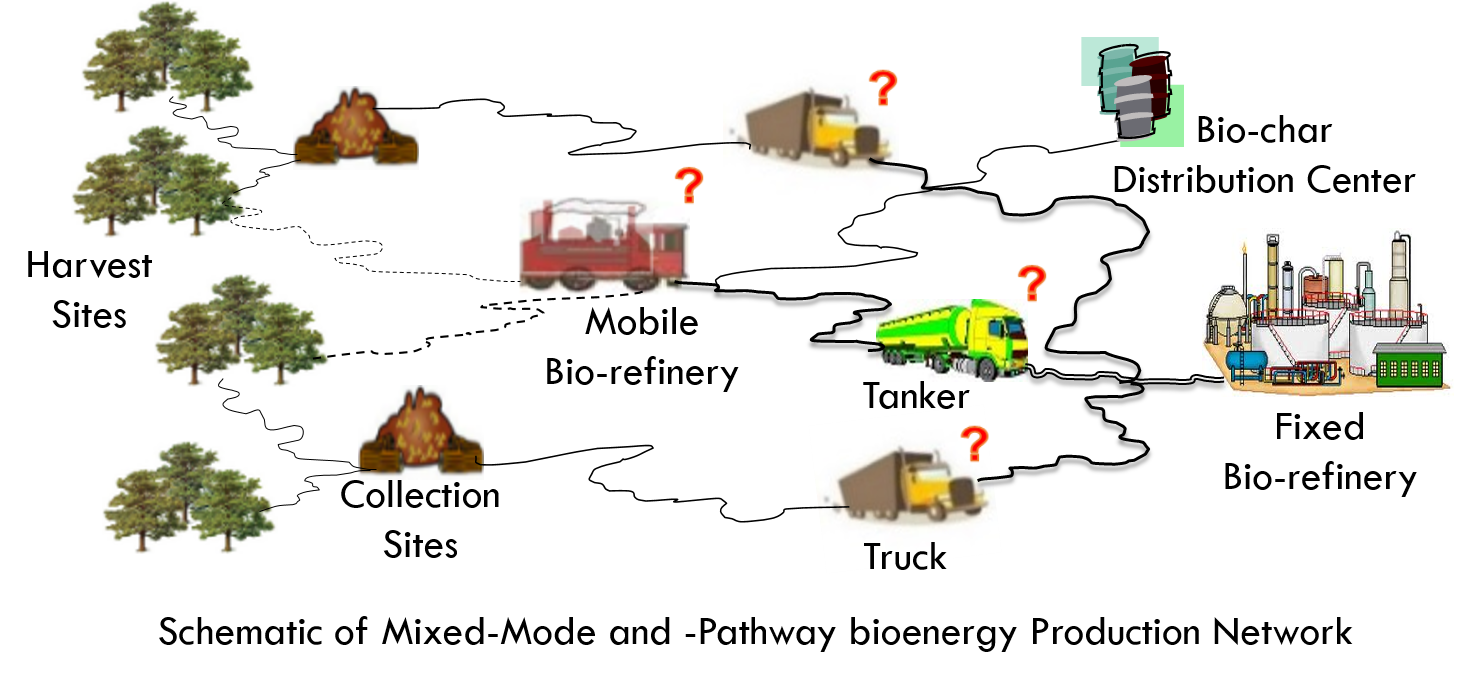

Thrust 3. Energy Systems: This research thrust is expected to develop sustainable engineering methods that can be applied in the analysis of alternative energy systems and industrial energy consumption.

Graduate and Undergraduate Research Opportunities

Students interested in conducting research that addresses economic, social, and/or environmental sustainability of manufactured products and manufacturing processes and systems are encouraged to contact Dr. Haapala.