Click here for Current Research Summaries

Bulk metallic glasses (BMG) can exhibit favorable properties relative to traditional crystalline metals such as near theoretical strength coupled with metal like fracture toughness values. However, BMGs also exhibit unique characteristics such as 1) fatigue endurance strengths that can range widely for different compositions with similar tensile strength and 2) ductility and strain softening/hardening behavior that is dependent on both sample size and loading configuration. In order to expand the application of BMGs into more structural and mechanical components designers need to ensure the components will not fail unexpectedly. To achieve this a detailed understanding of the unique fracture and fatigue characteristics of BMGs is needed. The BMG with composition Zr52.5Cu17.9Ni14.6Al10Ti5 exhibits excellent fatigue endurance strength in four point bending with a ratio of 107 cycle endurance strength to ultimate tensile strength of ~0.25, although small amounts of casting porosity can reduce the endurance limit by ~60%. This behavior was attributed to a relatively high fatigue threshold (ΔKTH ≈ 2 MPa√m) and an insensitivity to degrading environmental effects in ambient air compared to other Zr-based BMGs that exhibit very poor fatigue endurance strengths. Also, other factors found to influence the fatigue response include structural relaxation and residual stresses. Next, the issue of size dependent fracture behavior was also examined for the Zr52.5Cu17.9Ni14.6Al10Ti5 BMG and it was found that when sample size requirements of ASTM standard E399 were met the fracture toughness values are sample size and geometry independent. However, if ASTM standard E1820 is applied to allow smaller sample dimensions the results become sample size dependent in a manner that is distinct from crystalline metals.

Research has been funded in part by the Alexander von Humboldt Foundation Friedrich Wilhelm Bessel Research Award and the Arthur E. Hitsman Faculty Scholarship

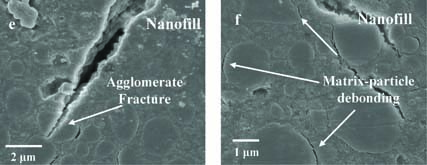

Dental restorative materials must satisfy a diverse set of property requirements such as matching the optical/aesthetic appearance of tooth tissue, being geometrically stabile and biocompatible with the tooth tissue, along with having adequate strength, fracture toughness and fatigue resistance. While modern resin based dental restorative composites are excellent in their aesthetic properties, they often have shortcomings in the other areas that lead to premature failures, most commonly by secondary caries development or mechanical failure of the restoration. For posterior teeth, and depending on the restoration class, annual failure rates up to 15% and average restoration lifetimes less than 6 years have been reported. Generally, strategies are needed to improve the mechanical performance and secondary caries resistance without sacrificing the aesthetic properties. For mechanical performance, our laboratory has shown the approach of using a hierarchical structure of large reinforcements made from smaller nanoparticles shows promise. When compared to traditionally reinforced composites and natural hard tooth tissues, fracture toughness and fatigue crack growth experiments have demonstrated that the same toughening mechanisms of crack deflection and crack bridging can be achieved; however, challenges to improving mechanical performance have been identified as optimizing the microstructure morphology and getting adequate bonding of the nanoparticle agglomerate reinforcements to the resin matrix. To promote improved secondary caries resistance, composites containing bioactive glass (BAG) have been developed with the goal of providing a locally anti-bacterial environment to hinder biofilm growth while also providing ions to aid in remineralization of lost tooth tissue. BAG containing composites have been produced with adequate mechanical and aesthetic properties, and to assess their secondary caries resistance a first ever system has been designed and constructed to grow biofilms on restorations in human tooth tissue samples during in-situ cyclic mechanical loading. Recent results show reduced bacterial penetration into gaps at the tooth-restoration margin for BAG containing composites.

Research is funded by the National Institute of Dental and Craniofacial Research (NIDCR)

Fossil, nuclear, and concentrated solar power generation systems all rely on elevated temperature turbines to generate electricity, and nickel based superalloys are needed to withstand the extreme environments experienced in these systems. Current research is focused on better understanding and predicting the elevated temperature fatigue and creep fatigue behavior of nickel based superalloys for gas turbines, advanced ultrasupercritical steam turbines, and very high temperature nuclear reactors.

Research is funded by the US Department of Energy's National Energy Technology Laboratory (NETL) and Nuclear Energy University Program (NEUP)

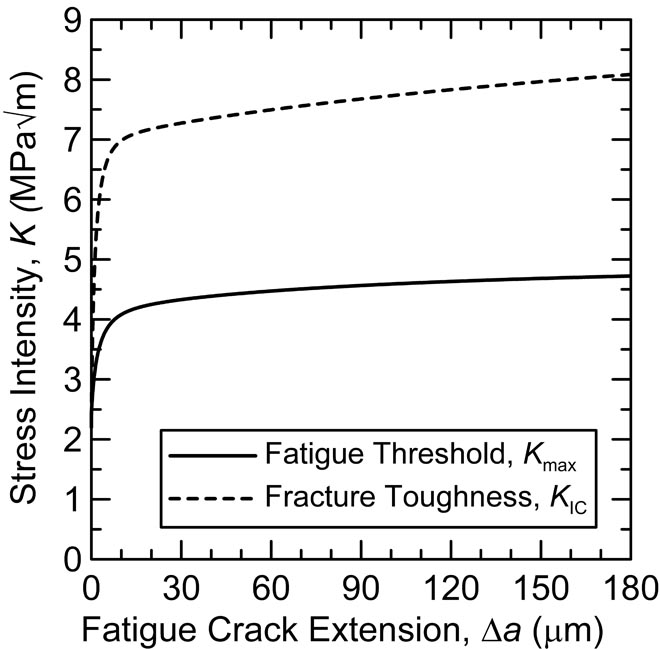

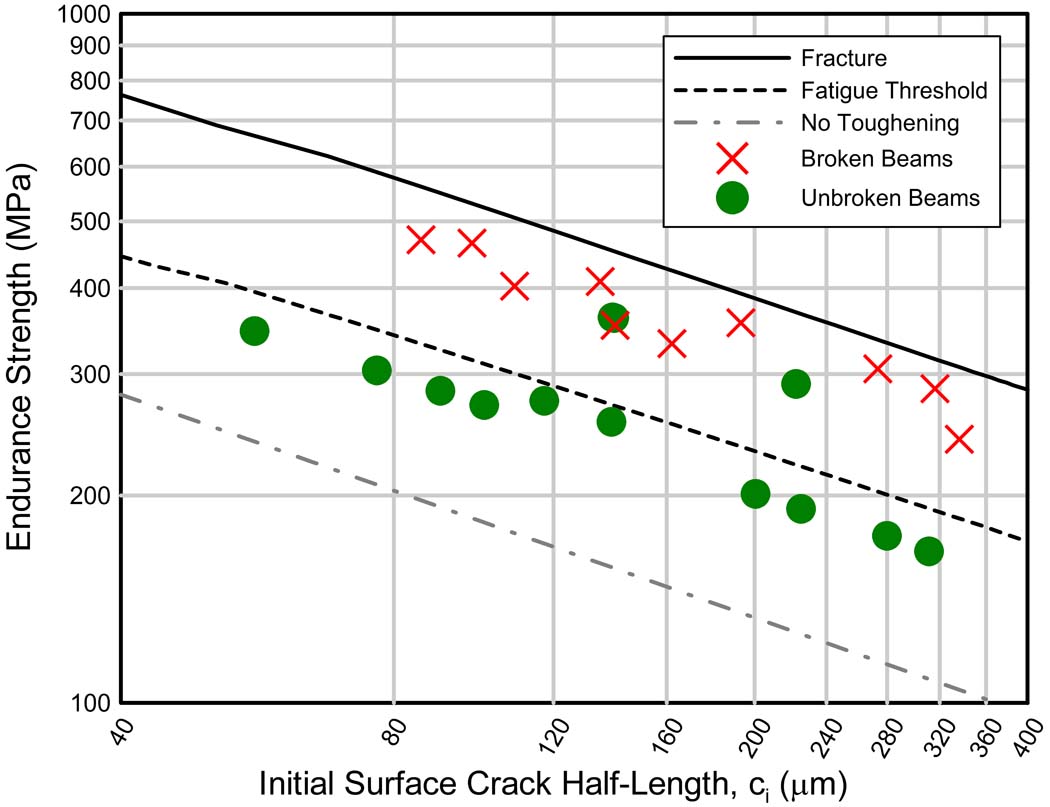

Crack bridging is an effective mechanism for achieving high toughness and strength in many ceramics and composites. However, this mechanism results in a crack size dependence for the fracture properties (R-curve effect) and fatigue properties (small crack effect) when crack sizes are on the order of the bridging zone size. Since brittle materials can only tolerate small crack sizes, making accurate fatigue predictions requires approaches that account for crack size effects. Here it is proposed that fatigue threshold R-curves (Fig. 1) may be used to understand and predict the fatigue behavior of bridging ceramics. In this study, fatigue threshold R-curves are determined for Al2O3 and Si3N4 ceramics and then are used to make fatigue endurance strength predictions for realistic semi-elliptical surface cracks. Furthermore, it is shown that the fatigue threshold R-curve can be determined by quantifying the bridging stress distribution for conventional long crack compact tension specimens without the need for difficult small crack experiments. Also, different methods for determining bridging stress distributions are compared. Finally, it is shown how experimentally measured fatigue data for realistic semi-elliptical surface cracks agrees well with predictions based on quantitative bridging zone characterization (Fig. 2). Overall, it is expected that this methodology will be extendable to cover a wide range of materials toughened by crack bridging, including ceramics, intermetallics, composites, and biological materials.

This research was funded by the National Science Foundation.