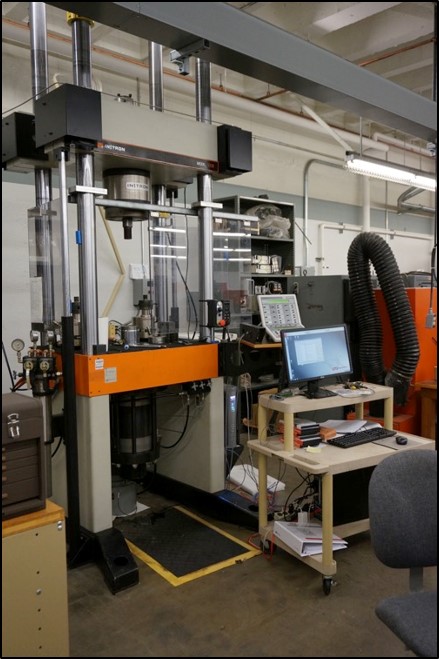

Instron servo-hydraulic test-frame: 100 kip and 0.2 kip load cells, 200 kip frame rating

MTS servo-hydraulic test-frame: 300 kip load cell, 400 kip frame rating

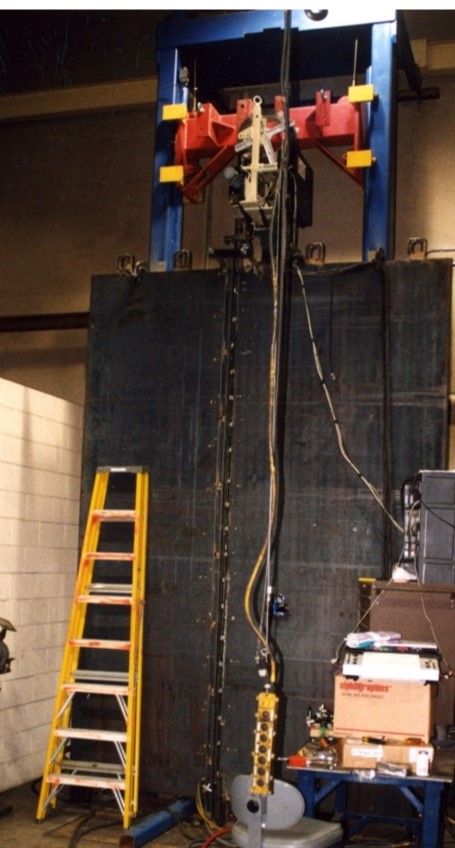

Research Inc drop tower: 2000 ft-lb capacity

Dead Weight loading systems: 3 systems (each 10 kip capacity)

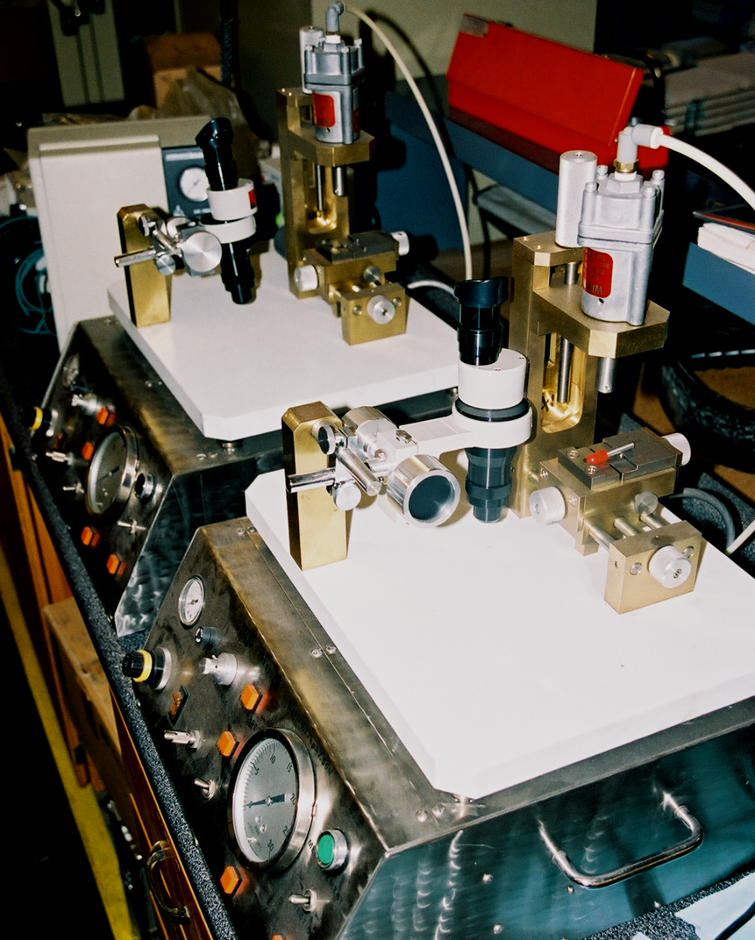

Gleeble 3500 dynamic servo-hydraulic test system: 10 t compression/tension capability, strain rates 0.0001/s to 50-60/s; with non-contact green-LED extensometer and 1600 °C pyrometer system

Flex bending fatigue: 5 systems (55 Hz fully reversed loading)

Automated computer controlled test procedures: (K1c,CTOD, J, da/dn, da/dt, K1scc, Kth, Tensile, Bend, flexure, compression)

Tinius Olson CVN (264 ft-lb pendulum type with low blow and instrumented setup)

Welding processes in house: OAW, SMAW, GMAW, FCAW, GTAW, SAW, ESD, ESW, ESS, CMT

Dual Motoman GMAW welding robots with coordinated positioner

Electroslag welding workstation

Fully digital Cold Metal Transfer and Timed Twin dual Gas Metal Arc Welding (Fronius)

Electro-slag strip surfacing

Lab-scale VIM/VAR with zirconia/alumina crucibles (1-3 kg)

Pilot-scale ESR (5-100 kg)

Gleeble 3500 system: Resistive heating to 1600 °C in high vacuum, < 10^-4 Torr

ATS clam-shell type furnace: 1700 °C air, 1600 °C inert gas with quench in vertical alumina tube

Marshall vertical tube furnace: 870 °C air or controlled atmosphere with direct quench

Leco horizontal tube furnace: 1250 °C air or controlled atmosphere

Thermcraft box type air furnaces: 300 °C, 1100 °C, and 1250 °C

Neslab ultralow temperature bath : -75 °C (-100 °F) immersion, Chest type -85 °C (-120 °F) in air

Across International GCF1200 Vacuum furnace: 1200 °C, vacuum to 15 mTorr, optional external gas supply

Jominy test fixture

Struers Accutom 50 precision saw

Buehler low-speed diamond saw

Struers Discotom cut-off saw

Leco 14" abrasive immersion cut-off saw

Struers Rotopol automated grinding/polishing system

Manual grinding/polishing stations 150/300 rpm (3)

Struers hot-mounting press

Struers/Allied cold mounting epoxy setup

Thermo-Calc/Dictra/Prisma: Thermodynamic, diffusion and precipitation modeling, databases for Fe, Ni, Ti, Slag

JMatPro: Materials Properties of alloys, databases for Fe, Ni, Ti, Al

DEFORM/DEFORM-HT: Metal Forming Process Simulation and Metal Heat Treatment

Abaqus, Ansys, Solidworks

DFT (VASP), MD (LAMMPS), etc. on HPC with 16+ TeraFlops, 1,800 cores

Gleeble 3500

Flex Bending Fatigue

Dual Robot GMAW