Physical simulation of flow behavior for engineering and structural alloy systems

Testing and investigation of material manufacturing routes for various alloy systems, design of multivariant processing maps

Determination of thermo-physical properties and phase transformations (CCT, TTT diagrams, CTE, melting point, etc.)

Large-scale structural welding using electro-slag welding and electro-slag strip surfacing

Wire-based Additive manufacturing using CMT/CMTadvanced on aerospace grade Al-alloys, Ni-based alloys

Numerical modeling of HAZ effect on residual stress in steel welds

CALPHAD-assisted design of high temperature alloy systems: Equilibrium phase diagrams, Scheil solification plots, homogenization treatments

VIM/VAR lab-scale casting of model alloys for rapid material development and sample testing

Pilot-scale ESR casting for slag studies to improve cleanliness and scalability studies together with manufacturing systems at NETL, Albany, OR

The project is broken up into three distinct parts, alloy melting, thermophysical property determination and wear property determination. High purity alloys will be generated with either VIM or ESR. Thermophysical properties will be determined using the Gleeble 3500. Finally, the wear properties of the developed alloys will be determined using standard industrial recognized test.

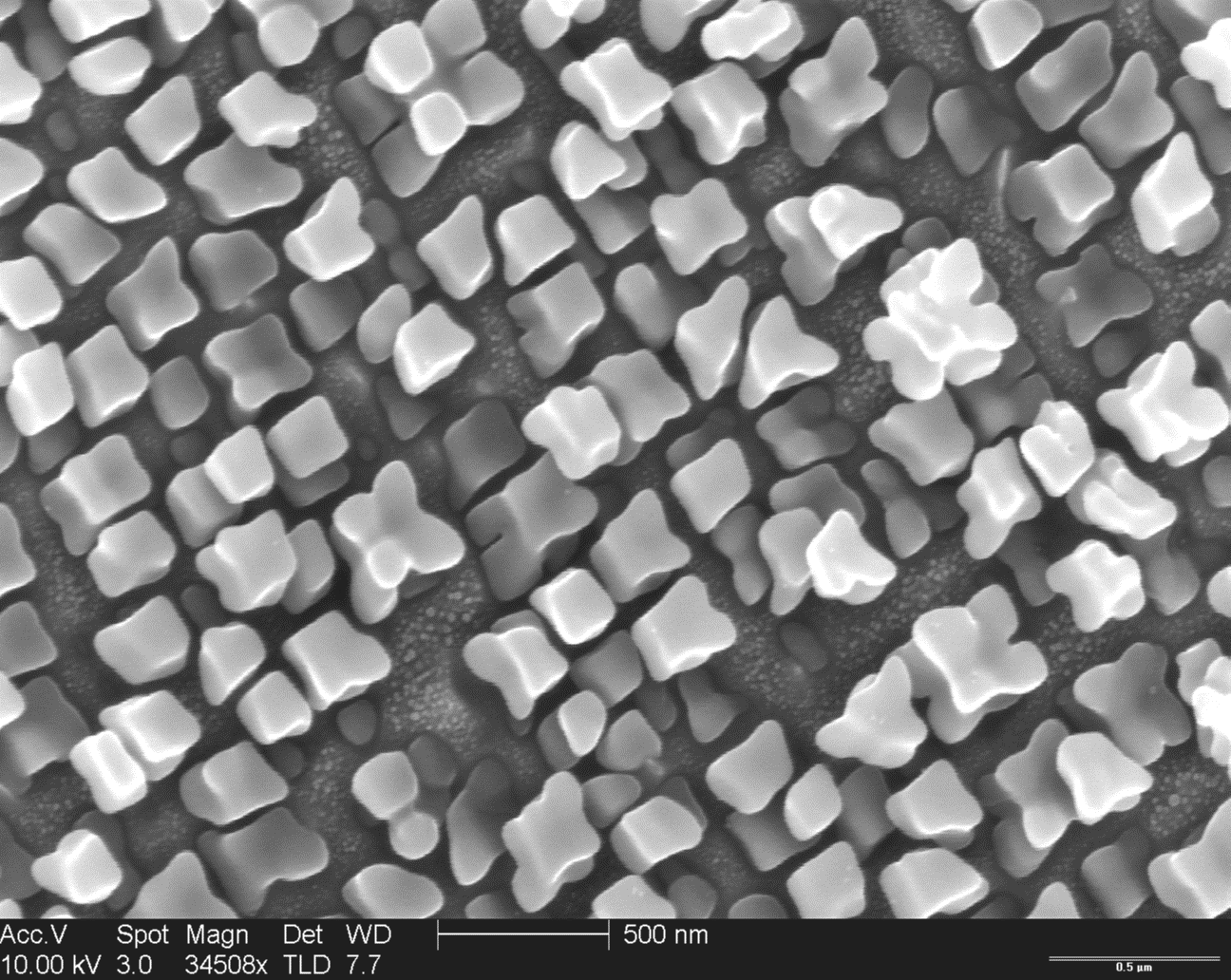

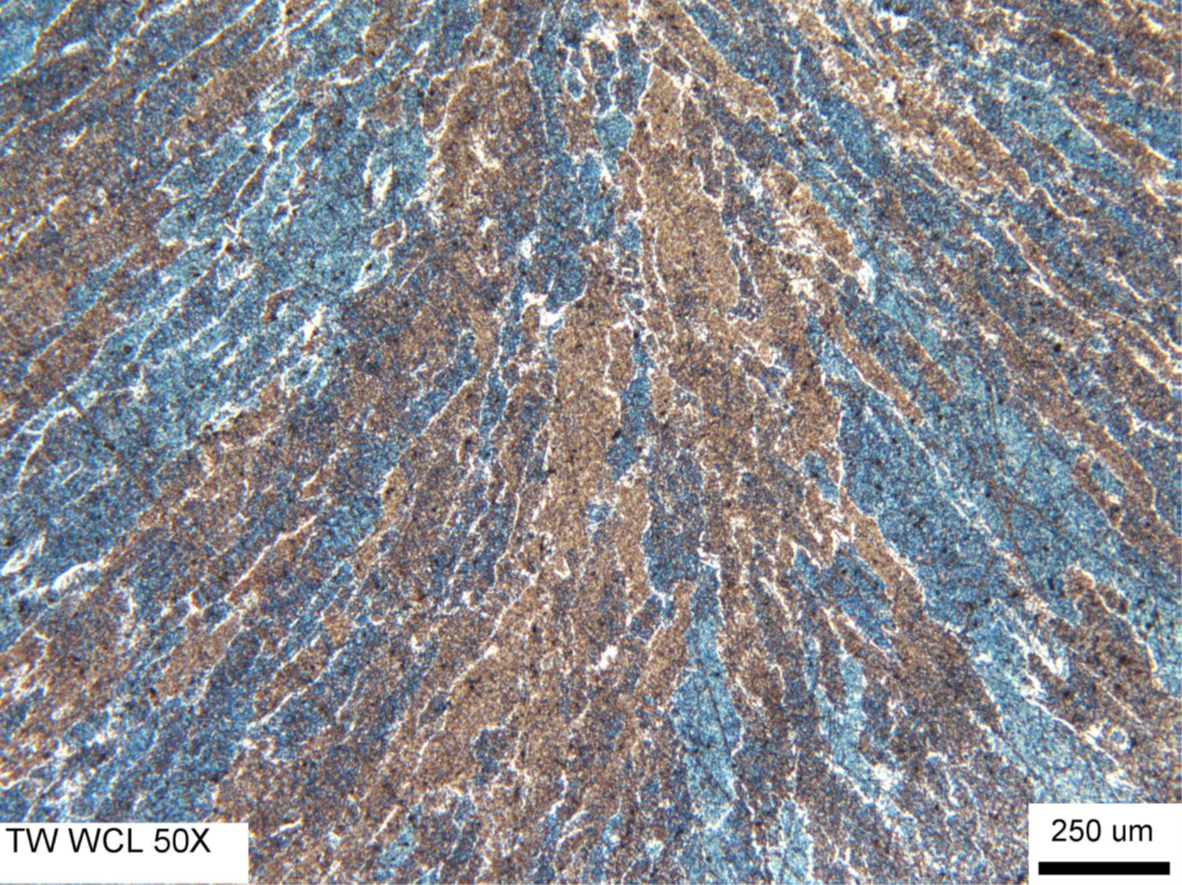

Understanding and controlling properties of steel is a key aspect of modern steel making practice. This is primarily accomplished for a particular alloy through combination of deformation and controlled cooling. This project will use the Gleeble to help determine continuous cooling transformations for a selection of high performance steel products. Extensive SEM/EBSD and FIB/TEM work will be done to determine the phase composition for each of the cooling curves to help with the understanding of the final properties achieved and provide a pathway for further improvements.

Forging of high-temperature alloys containing significant alloying additions for strengthening and creep resistance can result in cracking during the forging process. The high melting point of nearly 2400°C for these aerospace alloys means that even a high forging temperature is less than the threshold for conventional hot working. Forging of the as-cast ingot is the first step in the conversion process. Additionally, the design of new alloys for high-performance applications demands a fuller understanding of the deformation mechanisms and failure modes that are active in such alloys at various use conditions.

The goal of this research is to determine the underlying mechanisms that control deformation and failure of niobium alloys. This objective addresses both near—term manufacturing operations and long-term alloy design consideration. ATI will provide the test material for the deformation processing and microstructure analysis. PSU will use the Gleeble 3500 test system to simulate relevant thermomechanical conditions for these materials, and will use its metallography and electron microscopy facilities to identify deformation characteristics, crack paths, and microstructural effects on material behavior.

Hot working of metals with significant alloying additions, such as nuclear-grade zirconium alloys and high-temperature niobium alloys, can result in strain localization and cracking. Alloy development for the next generation of nuclear reactors requires data to aid in manufacturing scale-up of promising alloy concepts. Refractory alloys are often difficult to hot work in a conventional temperature range due to their extreme melting points. Forging of an as—cast ingot is the first step in the conversion process and is prone to defects such as strain-induced porosity and cracking. Furthermore, subsequent hot working steps such as rolling or extruding can create or exacerbate these defects. This is especially true for new materials for which there is little available data.

The goal of this research is to develop formability maps for zirconium and niobium alloys that take into account temperature, strain rate, strain, and starting microstructure. This objective addresses both near-term manufacturing operations and long-term alloy design consideration. ATI will provide the test material for the deformation processing and microstructure analysis. PSU will use the Gleeble 3500 test system to simulate relevant thermomechanical conditions for these materials, and will use its metallography and electron microscopy facilities to quantify flow stress, flow instability, and workability.

Hydrogen absorption is a key step in the in the formation of metal hydrides. The goal of this research is to determine the underlying effects of alloy additions and processing conditions on the hydride formation of a range of reactive metal alloys. DSC/TGA analysis will be used to generate the hydrogen absorption curves for the alloys of interest. Scope of the project will focus on establishing the equilibrium properties of hydrogen in a range of reactive refractory alloys to establish whether the behavior mimics that of the pure elements and if not, elucidate the ternary effects of alloy additions. Diffusion constants for hydrogen are low enough that the proposed method will allow near real-time equilibration of samples to the environment. Validation of this relatively high-throughput technique will allow efficient exposure to a variety of hydrogen concentrations to rapidly reveal the shape of the pressure-concentration isotherms and any mechanistic changes that occur with the addition of solutes in the reactive metal matrix.