During the Fall 2025 term, the Industrial Sustainability Lab (ISL) partnered with Continuum Powders to assess the environmental performance of nickel (Ni) powder production. Ni-based powders are a critical input for additive manufacturing. As concerns over climate change, resource scarcity, and sustainable industrial development continue to grow, manufacturers are increasingly challenged to reduce the environmental footprint of their final products and the upstream processes that support them.

Led by doctoral student David Okenwa and Dr. Karl Haapala, the study used life cycle assessment (LCA) to compare conventional powder production using virgin nickel with alternative approaches that incorporate recycled nickel.

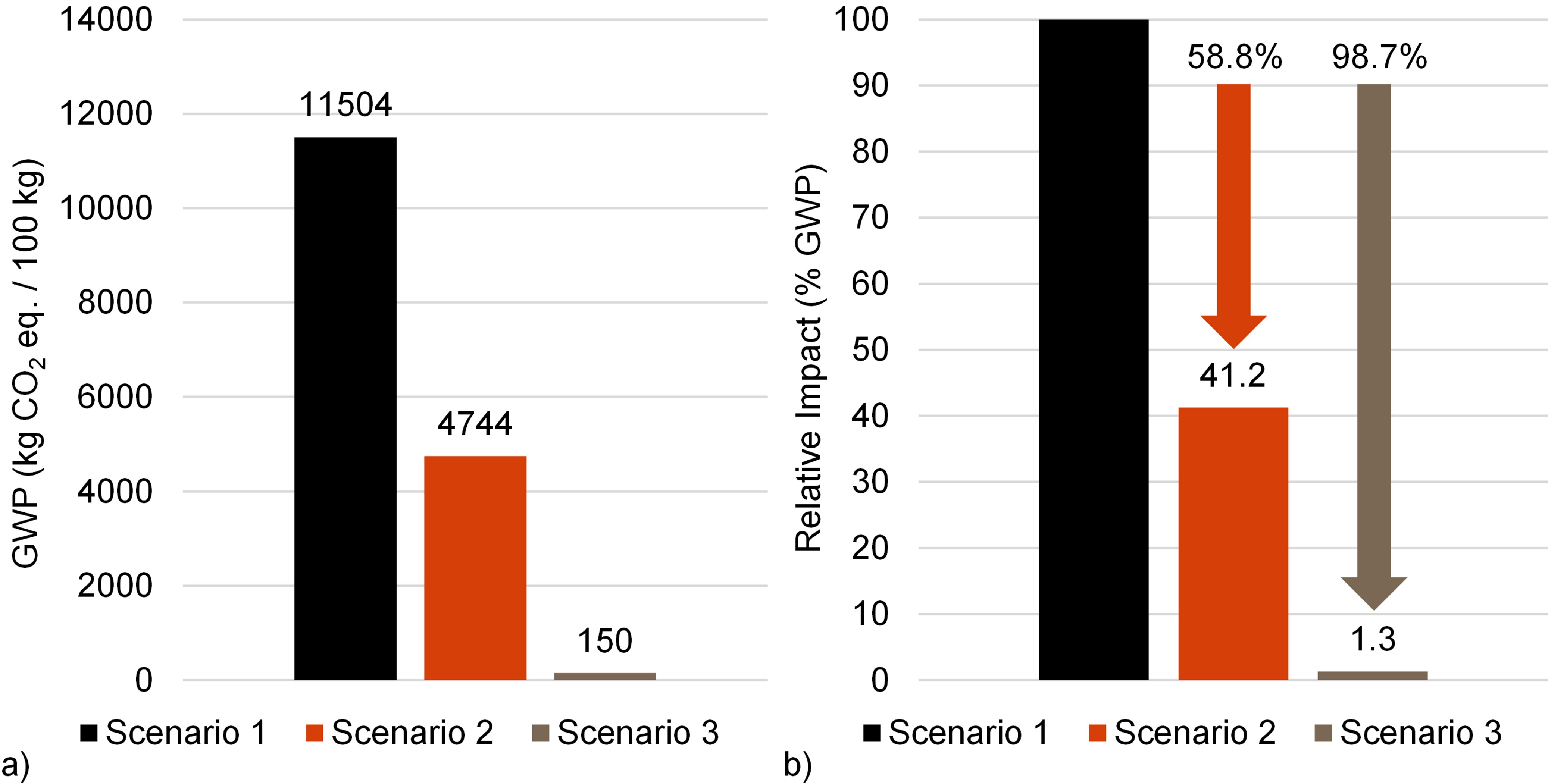

Three production scenarios were evaluated. Scenario 1 modeled conventional gas atomization using 100% virgin nickel, while Scenarios 2 and 3 examined plasma arc atomization, which enables reuse of unatomized material and relies on recycled nickel. Scenario 3 further explored the benefits of combining recycled materials with green electricity and consumables.

Figure 1: Impact of NI powder production under the three selected scenarios A) GWP and B) relative reduction in GWP.

Results show substantial environmental benefits from recycled material pathways. Scenario 1 had the highest impacts, with virgin nickel production contributing 62% of global warming potential (GWP). Scenario 2 reduced GWP by 58.8%, while Scenario 3 achieved a 98.7% reduction relative to the conventional baseline.

The full study can be accessed here.

ISL gratefully acknowledges the support of ISL alum Dr. Kamyar Raoufi of Kennesaw State University, and the Continuum Powders team, whose industry expertise was critical to this work.