Accomplished Projects:

Our objective is to improve the packing density of 316L stainless steel samples produced via SLM by using a bimodal powder size distribution. Primary powder of a larger size range is combined with a smaller particle size that fills the interstitial regions between the larger particles. The packing density and flowability of the mixed bimodal feedstock powder is determined by measuring tap density and Hausner ratio. Maximum tap density of the bimodal size distributions was up to 2% greater than the normally distributed powder. This project is funded by ATI, Oregon Metal Initiative (OMI) and Oregon Manufacturing Innovation Center (OMIC). Hannah is working on this project.

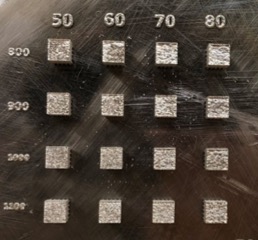

SLM paramaters optimization using 316L with bimodal powder size distribution as feedstock .

Dr. Pasebani and Hannah are discussing on the role of laser processing parameters on the parts built by SLM process in OR Creator machine

304L austenitic stainless steel is a structural material with superior mechanical properties, good corrosion, and oxidation resistance properties. Our objective is to embed nanoparticles to 304L matrix to improve high-temperature microstructural stability and mechanical properties through oxide dispersion mechanism. Our approach will overcome current challenges in conventional manufacturing of oxide dispersion strengthened (ODS) alloy (numerous steps such as mechanical alloying (MA) and hot consolidation making conventional manufacturing of ODS alloys costly, time-consuming and incapable of scale-up).This project is funded by US DOE and RAPID Institute. Milad is working on this project.

In this project water atomized and gas atomized Inconel 625 powder are used in a Binder Jetting process. We are focusing on process optimization, investigation of the microstructure and measuring mechanical and corrosion properties at room and elevated temperatures. This project is funded by Oregon Business Development Department High Impact Opportunity Program. Sarah is working on this project.